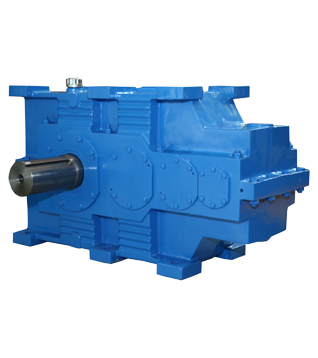

Helical gearboxes are generally used on machinery where actions need to work at higher speed ranges (hotel & catering industry machinery) or lower sound levels (automotive or air conditioning industries). They are also commonly used on machines where high torque transmission along parallel axes is required.

These gearboxes can be split into two types – gears that transmit power between parallel shafts and gears that transmit power between non-parallel shafts also known as cross-axis gears.

Helical gearboxes are extremely popular in small-scale and large-scale industries

Applications of Helical Gearboxes

Industrial gearboxes are available in two types – spur and helical gearboxes and they have very different abilities. Choosing the right gearbox largely depends on the requirement. If your objective is to reduce noise, helical gearboxes are the best bet. In helical gearboxes, the gear train operates at medium and high speeds and cuts down the noise.

Helical gearboxes are widely used across industries and are a preferred gear type due to the noise reduction it offers. For instance, in the automobile industry, helical gears are used for forwarding speeds. You can see the difference for yourself. Have you noticed the sound a manual transmission automobile makes when driven in reverse? This is because spur gears are used for reverse action in an automobile. Helical Gearboxes are used for forwarding movement and hence the noise is considerably low.

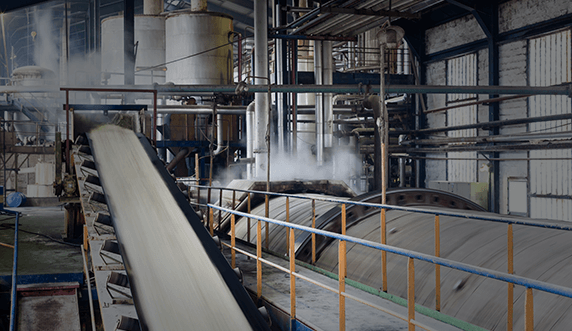

On the other hand, if space and weight are limitations, spur gears are a better fit because the need for thrust-carrying bearings is limited. Besides the automotive industry, helical gearboxes are also used in the textile, plastic, and food industries. They are also an integral component of conveyor belts, blowers, elevators, compressors, and cutters. The effective load-sharing capacity between the teeth of a helical gearbox has led to its widescale adoption in heavy work sectors including earthmoving, fertilizers, and printing industries.

Single, Double, and Herringbone Gearboxes

In single gearboxes, the teeth are placed at a certain angle to the axis. As a result, the orientation of this industrial gearbox may be right or left. Due to their orientation and design, single helical gearboxes have large load capacities and are used extensively in high-load applications.

Double helical gearboxes have two helical surfaces placed against each other. Both these surfaces have similar teeth placed at opposite angles. These gearboxes offer high-loading capacity and steady transmission. As a result, they are widely used for power transmission in gas turbines, generators, prime movers, pumps, fans, etc. They are also used in marine ships and construction machines.

Herringbone gearboxes look similar to double-helical gearboxes but are different because there is no gap separating the two surfaces. These gearboxes are smaller in size and find application in high-shock and vibration applications.

Reach Out for All Your Queries Regarding Material Lifting Machines

Santram Engineers have decades of experience in the manufacture of material lifting machines and Power Transmission Products. It is the largest distributor and stockiest for Premium Transmission Limited.

For any queries related to helical gearboxes, geared and gearless material lifting machines, you can reach out to our experts for consultation by calling us at +91-96247 39393 or writing to us at sales@santramengineers.com. We would be happy to help!