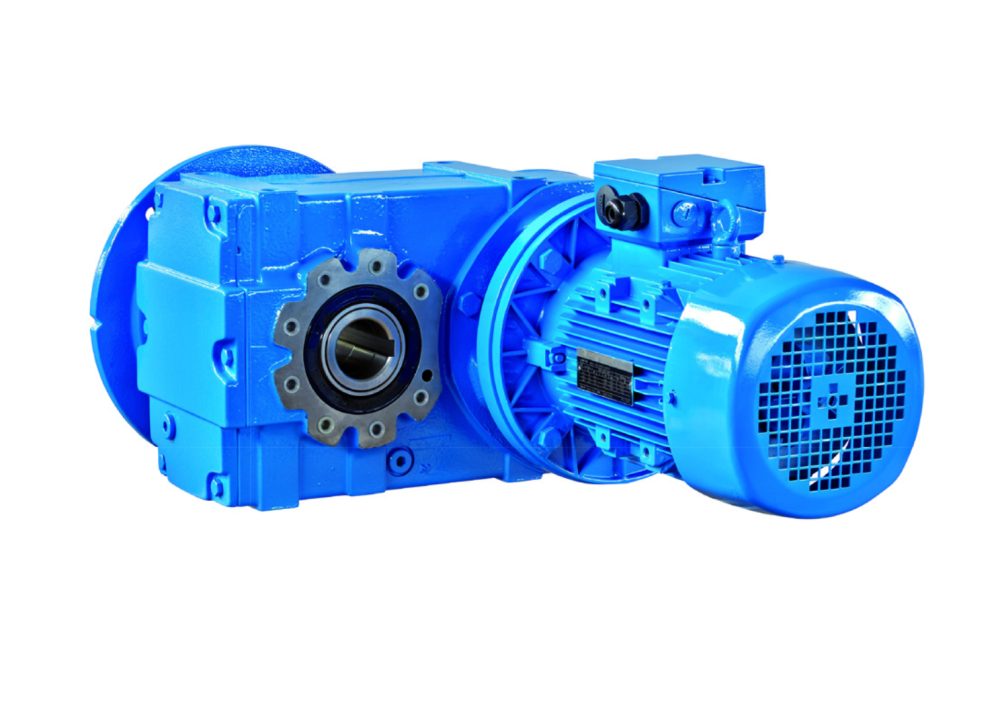

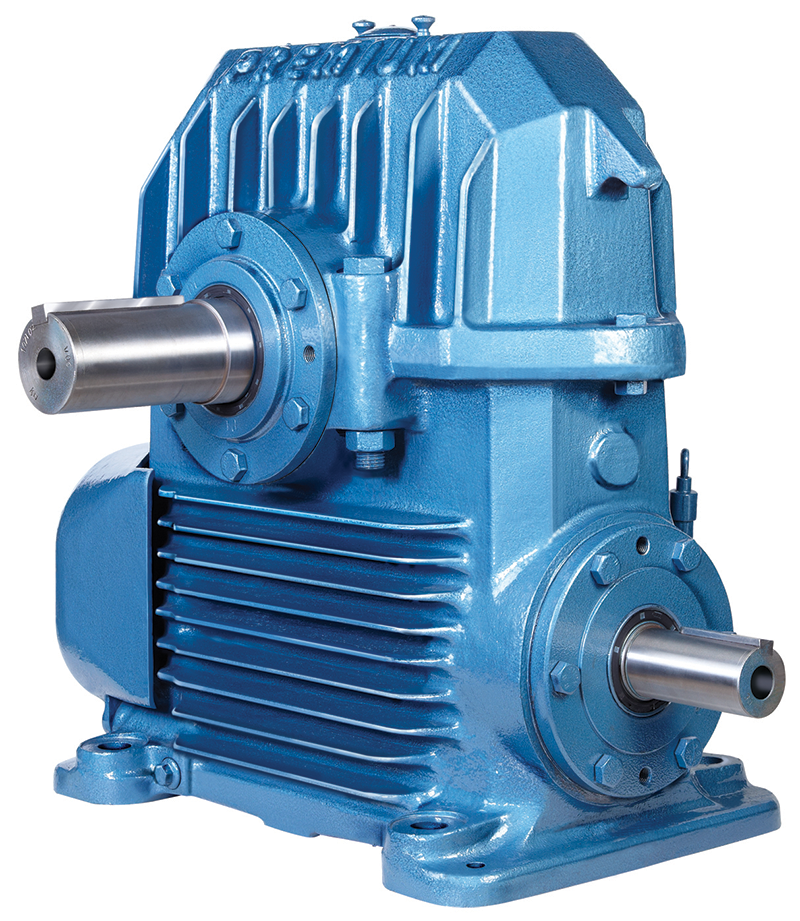

A gear motor is also called a geared motor/gear motor, it is a blend of an electric engine and gearbox or gear framework. When having questions like” what does a geared engine mean?” or “What are Geared Motors?” basically you are thinking as to how a gear motor is valuable for your organization’s items or production. These geared motors are effective on the grounds that you will just need to mount them and you can operate one framework, rather than operating several others.

Gear motors, for the most part, consolidate an effective engine, for example, an Electrically Commutated Motor, along with a gear reducer/gear head. These combinations have proved to be an incredible method to limit alignment issues. You don’t need to stress over independently to coordinate gears for engines; rather, you will be able to work with a single motor and gear.

Gear motors are usually a part of gadgets, like: can openers, garage doors, washing machine’s time control handles and even electric alarm clocks. Regular commercial utilization of a gear motor incorporates hospital beds, cranes and numerous different applications that are too many to list.

Basic Operational Principle

A gear motor is incorporated within an AC or a DC electric engine. It’s seen that most of these gear motors yield around 1,200 – 3,600 cycles per minute(RPMs).

Normal speed and stall speed torque determinations are the 2 distinctive speed particulars that these gears have.

Performance Specification:

Gear proportion: The velocity ratio of the input gear in regard to the velocity of the output gear is the gear ratio in a Gearbox.

Torque: Torque is the angular power that is generated in order to handle the load.

Speed: Speed is the shaft rotational speed that is generated by the motor

Gearbox productivity: The % of torque/power transferred by a gearbox is the gearbox productivity.

Backlash: The angle at which the output shaft rotates without the input shaft movement.