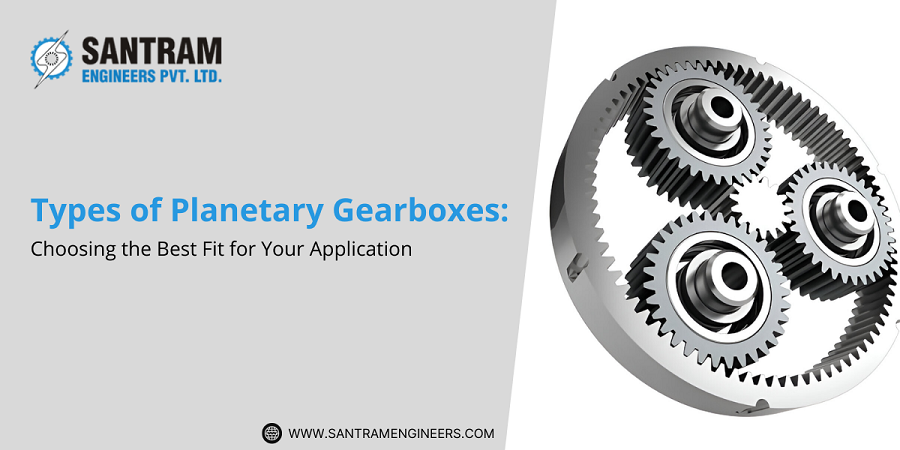

Planetary gearboxes are among the most efficient and compact gear systems, widely used in industries such as automation, robotics, automotive, and heavy machinery. Known for their high torque density, durability, and smooth power transmission, these gearboxes are essential for applications requiring precision and reliability. With multiple configurations available, selecting the right type is crucial to achieving optimal performance in any operation.

This guide explores different types of planetary gearboxes and their suitability for various applications, helping industries choose the best fit for their specific needs.

How Planetary Gearboxes Work

Basic Structure: Sun Gear, Planet Gears, and Ring Gear

A planetary gearbox consists of three main components:

- Sun Gear – The central gear that transmits power

- Planet Gears – Smaller gears that revolve around the sun gear

- Ring Gear – An outer gear that holds the planet’s gears in place

These elements work together to create a compact and highly efficient transmission system that can handle high loads with minimal space requirements.

Working Principle and Advantages Of Conventional Gear Systems

Unlike conventional gear systems, planetary gearboxes distribute torque across multiple planet gears, reducing wear and increasing load-bearing capacity. This design offers:

Higher efficiency and torque output:

- Compact size for space-saving installations

- Smooth and reliable power transmission

- Reduced backlash and increased precision

Factors Affecting Performance and Efficiency

The performance of a planetary gearbox depends on factors like material quality, lubrication, gear ratio, and load conditions. Proper selection and maintenance ensure longevity and efficiency in demanding industrial environments.

Types of Planetary Gearboxes

1. Single-Stage Planetary Gearbox

A single-stage planetary gearbox has a simple design with only one reduction stage, making it compact and efficient. This type of gearbox is ideal for applications requiring moderate torque and speed control. With fewer components, it ensures minimal energy loss, lower maintenance, and a cost-effective solution for various industrial needs.

Key Benefits:

- Compact and lightweight

- High efficiency with minimal energy loss

- Suitable for applications with moderate torque requirements

Applications:

- Conveyors

- Pumps

- Packaging machinery

2. Multi-Stage Planetary Gearbox

For applications requiring higher torque output and greater reduction ratios, a multi-stage planetary gearbox is the preferred choice. This gearbox consists of multiple planetary gear stages, allowing for precise torque transmission while maintaining efficiency. It is commonly used in demanding industries where power and durability are essential.

Key Benefits:

- Higher torque transmission

- Greater reduction ratio capabilities

- Improved load distribution for heavy-duty applications

Applications:

- Track drives

- Winch drives

- Cutter head drives

3. In-Line Planetary Gearbox

An in-line planetary gearbox features a compact design where the input and output shafts are coaxial. This design ensures high efficiency and is commonly used in applications requiring precision and power transmission. The in-line configuration provides smooth operation and consistent torque, making it ideal for various industrial applications.

Key Benefits:

- Space-saving design

- High precision and efficiency

- Reliable power transmission

Applications:

- Wheel drives

- Conveyors

- Hoist drives

4. Offset Planetary Gearbox

An offset planetary gearbox offers a unique design where the input and output shafts are not aligned, allowing for flexible mounting options. This design is particularly useful in applications with space constraints or misalignment issues. It ensures smooth power transmission while adapting to specific design requirements.

Key Benefits:

- Allows flexible mounting configurations

- Suitable for misalignment and space constraints

- Ensures reliable torque transmission

Applications:

- Auger & drilling drives

- Mixing equipment

- Industrial automation systems

5. Coaxial Planetary Gearbox

The coaxial planetary gearbox has input and output shafts aligned on the same axis, ensuring minimal energy loss and high power transmission. Due to its compact and efficient design, it is widely used in applications that require precise control and high torque.

Key Benefits:

- High efficiency in power transmission

- Minimal space requirement

- Durable and reliable for high-load applications

Applications:

- Slew drives

- Hoist drives

- Industrial gear systems

6. Right Angle Planetary Gearbox

A right-angle planetary gearbox features a 90-degree power transmission mechanism, making it an excellent choice for applications with tight space constraints. It is commonly used in heavy-duty industrial machinery where compact installation is required without compromising efficiency.

Key Benefits:

- Allows compact and efficient power transmission

- Reduces space requirements in installations

- Suitable for high-torque applications

Applications:

- Sugar mill & boiler equipment

- Coil tubing injectors

- Specialised industrial machinery

7. Harmonic Drive Planetary Gearbox

Harmonic drive planetary gearboxes are known for their ultra-high precision and sero-backlash design, ensuring smooth motion control. These gearboxes are used in applications where extreme accuracy, efficiency, and smooth torque transmission are required.

Key Benefits:

- High precision and minimal backlash

- Smooth and reliable torque transmission

- Ideal for precision-controlled applications

Applications:

- Mixing equipment

- Robotics and automation

- Precision-controlled industrial applications

8. Differential Planetary Gearbox

A differential planetary gearbox allows variable speed output and smooth torque distribution, making it suitable for applications requiring differential torque control. It is commonly used in advanced track drives and robotic systems where precise movement and load balancing are essential.

Key Benefits:

- Enables variable speed control

- Ensures smooth torque distribution

- Ideal for advanced automation systems

Applications:

- Robotic systems

- Advanced track drives

- Automated industrial machinery

Select the Right Planetary Gearbox for Your Application

Here’s a table summarising the selection of the right planetary gearbox for each application:

| Application | Best Fit Planetary Gearbox |

| Wheel Drives | In-line planetary gearbox |

| Track Drives | Multi-stage planetary gearbox, Differential planetary gearbox |

| Conveyors | Single-stage planetary gearbox, In-line planetary gearbox |

| Slew Drives | Coaxial planetary gearbox |

| Hoist Drives | In-line planetary gearbox, Coaxial planetary gearbox |

| Mixing | Harmonic drive planetary gearbox, Offset planetary gearbox |

| Winch Drives | Multi-stage planetary gearbox |

| Pumps | Single-stage planetary gearbox |

| Coil Tubing Injectors | Right-angle planetary gearbox |

| Auger & Drilling Drives | Offset planetary gearbox |

| Cutter Head Drives | Multi-stage planetary gearbox |

| Sugar Mill & Boiler Equipment | Right-angle planetary gearbox |

Key Considerations When Choosing a Planetary Gearbox

1. Torque and Speed Requirements

Understanding the torque and speed needs of your application is crucial when selecting a planetary gearbox. Ensuring the right torque output prevents mechanical failures and enhances performance.

2. Space Constraints and Installation Factors

Some applications require compact gear solutions due to limited space. Choosing a gearbox with a space-efficient design ensures easy integration into existing systems.

3. Durability and Environmental Resistance

Industrial applications often expose gearboxes to harsh conditions such as extreme temperatures, dust, and moisture. Selecting a gearbox with high durability and environmental resistance ensures long-term reliability.

4. Maintenance and Efficiency Concerns

A well-designed planetary gearbox requires minimal maintenance while delivering maximum efficiency. Choosing a gearbox with optimised lubrication and wear resistance extends its operational life.

5. Cost-Effectiveness and Supplier Reliability

While price is an important factor, selecting a gearbox from a reputable supplier ensures quality and long-term cost savings. Reliable suppliers provide high-quality materials, warranty support, and after-sales services.

Key Takeaway

Selecting the right planetary gearbox depends on the specific requirements of the application, including torque, speed, space constraints, and load capacity. Each type offers unique advantages tailored to different industrial uses, ensuring efficiency, reliability, and longevity. By understanding the characteristics and applications of these gearboxes, businesses can make informed decisions to optimise their machinery and operations.

Find the Perfect Planetary Gearbox for Your Application – Expert Solutions from Santram Engineers

Choosing the right planetary gearbox is essential for maximising efficiency, durability, and performance in industrial applications. Santram Engineers, a trusted leader in gearbox solutions, offers a wide range of high-quality planetary gearboxes designed to meet diverse industry requirements. Our products are sourced from Premium Transmission, one of the leading gearbox manufacturers in India, ensuring superior reliability and performance for your operations.

Our expert team provides personalised guidance, ensuring you select the best gearbox for your specific needs. Whether you need a single-stage, multi-stage, or specialised planetary gearbox, we have the right solution for you.

Contact Santram Engineers at +91 96247 39393 or drop us an email at sales@santramengineers.com and experience superior engineering, reliable performance, and unmatched support. Optimise your operations with the best industrial gearboxes from a supplier you can trust!