Worm gearboxes are essential components of power transmission products, used in various industrial applications to reduce the speed of motors and other machinery while increasing the torque output. These gearboxes are more popular than other reduction gearboxes because of their high efficiency, low noise, and compact size.

A worm gearbox is a type of gear system that consists of a worm screw and a worm wheel. The worm screw is a cylindrical gear with a helical thread, while the worm wheel is a concave gear that meshes with the worm screw. As the worm screw rotates, it turns the worm wheel, causing it to rotate in the opposite direction. This system provides high torque amplification, making it ideal for heavy-duty applications.

Proper maintenance of worm gearboxes is essential to ensure optimal performance and longevity. This blog will discuss how to care for and maintain worm gearboxes, including regular inspection, lubrication, gearbox alignment, temperature monitoring, and troubleshooting common problems. By following these maintenance tips, you can extend the lifespan of your worm gearboxes and avoid costly repairs or replacements. So, let’s dive in and explore the world of worm gearboxes in more detail.

Maintenance of Worm Gearboxes

Regular Inspection

Regular inspection is essential to ensure the worm gearbox is operating correctly and to prevent any issues from becoming severe. Consider the following things during a review:

Visual Inspection

The first step in the inspection process is to perform a visual inspection. Look for signs of wear and tear, cracks, rust, and other signs of damage. Inspect the gears and bearings for signs of wear and damage. Make sure that the gearbox is clean and free of debris.

Lubrication Inspection

The lubrication system is essential for the proper functioning of a worm gearbox. During an inspection, you should check the lubrication system to ensure the lubricant is at the right level and free from contaminants. Check the oil level in the gearbox and make sure that the oil is not contaminated with water, dirt, or other contaminants.

Lubrication

Proper lubrication is vital for the smooth operation of a worm gearbox. It reduces friction and wear between the gears and bearings, extends the gearbox’s life, and helps prevent breakdowns.

Proper Lubricant Selection

Selecting a suitable lubricant for the gearbox is critical. The lubricant should be chosen considering the gearbox’s operating conditions, such as temperature and load. Also, follow the manufacturer’s recommendations to ensure you select the correct lubricant.

Lubricant Replacement

Replace the lubricant regularly to ensure that the gearbox remains well-lubricated. Follow manufacturer’s recommendations to know how frequently you need to replace the lubricant.

Lubrication Frequency

The frequency of lubrication depends on the operating conditions of the gearbox. In some cases, you may need to lubricate the gearbox daily, while in others, it may be less frequent. Factors that affect the frequency of lubrication include the load, temperature, and speed of the gearbox.

Gearbox Alignment

Proper gearbox alignment is critical for the efficient operation of a worm gearbox. Misalignment can cause excessive wear and tear, leading to premature failure of the gearbox. To ensure proper alignment, install and check the gearbox periodically for alignment issues.

Temperature Monitoring

Monitoring the temperature of the gearbox is essential to prevent damage and ensure that the gearbox is operating correctly. Check the temperature regularly, along with any abnormalities that need immediate attention.

III. Troubleshooting Worm Gearboxes

- Noise – explain the different types of noise that can indicate a problem with the gearbox and how to troubleshoot.

- Vibration – discuss the causes of gearbox vibration, how to identify the problem, and how to troubleshoot.

- Overheating – explain the causes of gearbox overheating and how to troubleshoot.

- Leakage – highlight the reasons why the gearbox can leak and how to troubleshoot.

Troubleshooting Worm Gearboxes

Worm gearboxes are an essential part of power transmission products, but like any other mechanical component, they can experience problems over time. Addressing these issues as soon as possible is crucial to ensure the gearbox’s longevity and optimal performance. Here are some common problems that may arise with worm gearboxes and how to troubleshoot them.

Noise

Noise is a common issue with worm gearboxes, and several factors, including worn gears, misalignment, and lack of lubrication, can cause it. Different types of noise can indicate different problems with the gearbox. For instance, a clicking or tapping noise may indicate worn gears, while a whining or grinding noise may point to misalignment or lack of lubrication.

To troubleshoot gearbox noise, start by identifying the type of noise and where it’s coming from. Next, inspect the gearbox for wear and tear, check the alignment, and ensure the lubrication system works correctly. In some cases, replacing the worn gears or realigning the gearbox may solve the problem. If the noise persists, seek the help of a professional gearbox repair service.

Vibration

Vibration is another common issue with worm gearboxes, and several factors, including misalignment, worn gears, and imbalance, can cause it. It can cause severe damage to the gearbox and other connected components, so it’s crucial to address the problem as soon as possible.

To troubleshoot gearbox vibration, start by identifying the source of the vibration and inspecting the gearbox for wear and tear. Check the alignment, and ensure that the gears are properly lubricated. If the problem persists, consider balancing the gearbox or replacing worn gears. It’s important to note that vibration can occur due to external factors, such as foundation problems, so it’s essential to rule out these factors before making any repairs.

Overheating

Overheating is a severe problem with worm gearboxes, and several factors, including lack of lubrication, overload, and misalignment, can cause it. It can cause severe damage to the gearbox and other connected components, so it’s crucial to address the problem as soon as possible.

To troubleshoot gearbox overheating, check the gearbox temperature and ensure the lubrication system works correctly. Look for proper alignment and ensure that the gearbox is not overloaded. If the problem persists, seek the help of a professional gearbox repair service.

Leakage

Leakage is a common problem with worm gearboxes. Worn seals, damaged gaskets, and cracks in the gearbox housing can cause it. The issue can lead to reduced lubrication, increased wear and tear, and other serious problems.

To troubleshoot gearbox leakage, start by inspecting the gearbox for signs of leakage, such as oil stains or wet spots. Inspect the seals and gaskets, and replace them if necessary. If the problem persists, check for cracks in the gearbox housing and consider replacing the gearbox if the damage is severe.

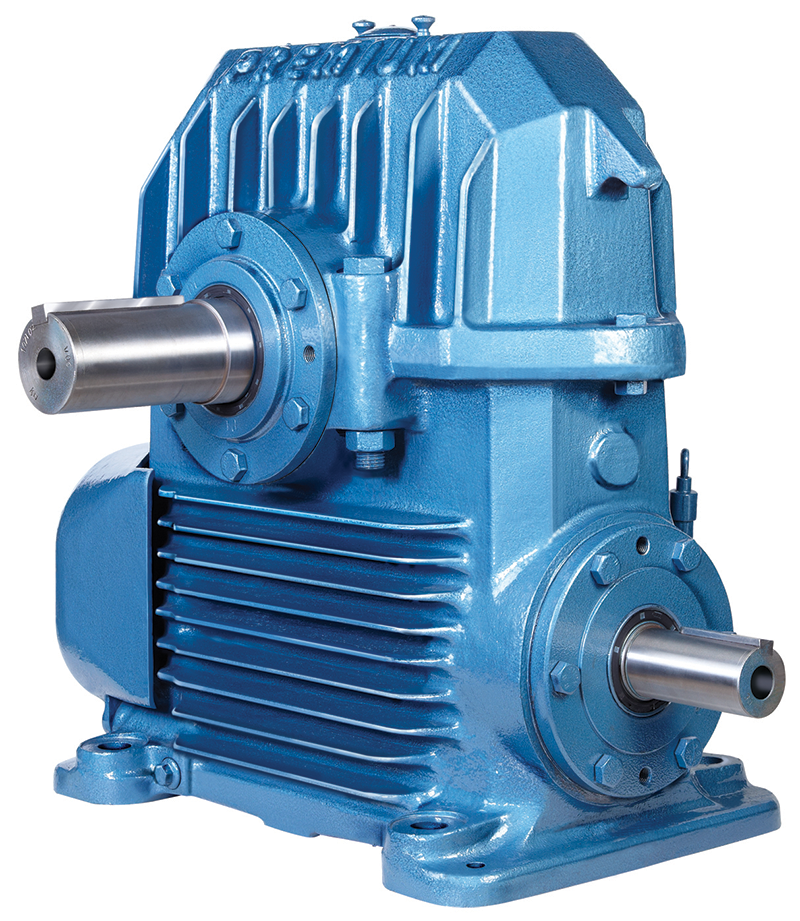

Where To Find The Best Worm Gearbox Manufacturers In India?

Are you searching for the best power transmission products, reduction gearboxes, and worm gear suppliers in India? Then look no further than Santram Engineers. We are India’s most trusted worm gearbox manufacturer with decades of expertise in the field. For assistance regarding worm gearboxes, you can call us at +91-96247 39393 or write to us at sales@santramengineers.com.