Selecting the right industrial gearbox is critical for ensuring the performance, durability, and efficiency of roller table applications. For businesses that rely on high-volume material handling—especially in environments involving extreme loads and continuous operations—the gearbox becomes the backbone of motion control and mechanical power transmission. Whether you operate in steel manufacturing, automotive assembly, or large-scale logistics, the correct gearbox specification can drastically reduce downtime, improve operational consistency, and increase the overall lifespan of your equipment.

As one of the leading gearbox dealers in Kerala, Tamil Nadu, Chennai, Delhi, Odisha among other states in India, we at Santram Engineers understand the evolving needs of industrial sectors. Our deep expertise in the field of industrial gearboxes enables us to guide clients toward efficient, cost-effective solutions for a wide range of applications.

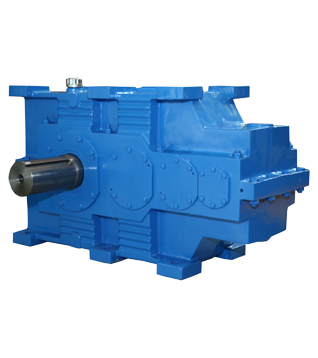

Role of Gearboxes in Roller Tables

Roller tables are vital components in various industrial systems, responsible for the movement of heavy or bulky materials across production lines or through processing stations. Here, the gearbox plays a crucial role in:

Power Transmission and Load Handling:

Industrial gearboxes ensure consistent torque and speed to handle heavy loads without compromising on stability or precision. The gearbox reduces the high input speed from the motor to a lower, more manageable output speed—crucial for moving materials safely and efficiently.

Ensuring Smooth and Controlled Movement:

Especially in systems requiring synchronised movement, gearboxes help maintain uniform motion and reduce jerks or vibration, which can otherwise damage the product or the system. Roller tables used in high-precision industries rely on gearboxes for seamless integration into automated production environments.

Key Industries Using Roller Table Gearboxes

Several industries benefit from the integration of robust, high-performance industrial gearboxes in their roller table setups:

Steel Mills and Metal Processing:

These facilities depend on gearboxes that can withstand intense loads, high temperatures, and continuous operations. Reliable roller table gearboxes are crucial for moving hot billets, slabs, or sheets through various stages of processing.

Automotive Manufacturing:

From moving chassis to handling engine blocks, roller tables fitted with heavy-duty gearboxes streamline production lines, increase accuracy, and reduce manual labour.

Heavy-Duty Material Handling:

Industries dealing with mining, bulk goods, or port logistics utilise roller tables with strong gearbox systems to manage the transportation of materials efficiently and safely.

Essential Factors to Consider When Choosing an Industrial Gearbox

When selecting an industrial gearbox for roller table applications, businesses must evaluate a variety of performance and operational factors. Choosing the wrong gearbox can lead to equipment breakdowns, increased energy consumption, and costly downtime.

1. Load Capacity and Torque Requirements

One of the foremost factors in gearbox selection is understanding the torque and load capacity your roller table will require:

Determining torque demands based on application: The torque needed depends on the weight of the materials being transported, the speed at which they move, and the required acceleration or deceleration. Gearboxes must be capable of handling peak torque loads without causing strain or failure.

Importance of high load-bearing capability: Industrial applications often deal with fluctuating or sudden loads. A gearbox with superior load-handling capacity ensures operational consistency even under demanding conditions, such as in steel plants or heavy-duty conveyor lines.

2. Gearbox Efficiency and Power Transmission

Efficiency is more than a technical detail—it directly impacts operational cost and energy consumption:

Impact on energy consumption and operational cost: An efficient gearbox minimises mechanical losses, translating into lower power usage and reduced utility expenses. For 24/7 operations, even a small improvement in efficiency can lead to substantial savings.

Efficiency rating and mechanical losses: Always verify the gearbox’s efficiency rating. Premium-grade industrial gearboxes offer optimised gear tooth design, minimal backlash, and precision alignment to reduce energy loss during transmission.

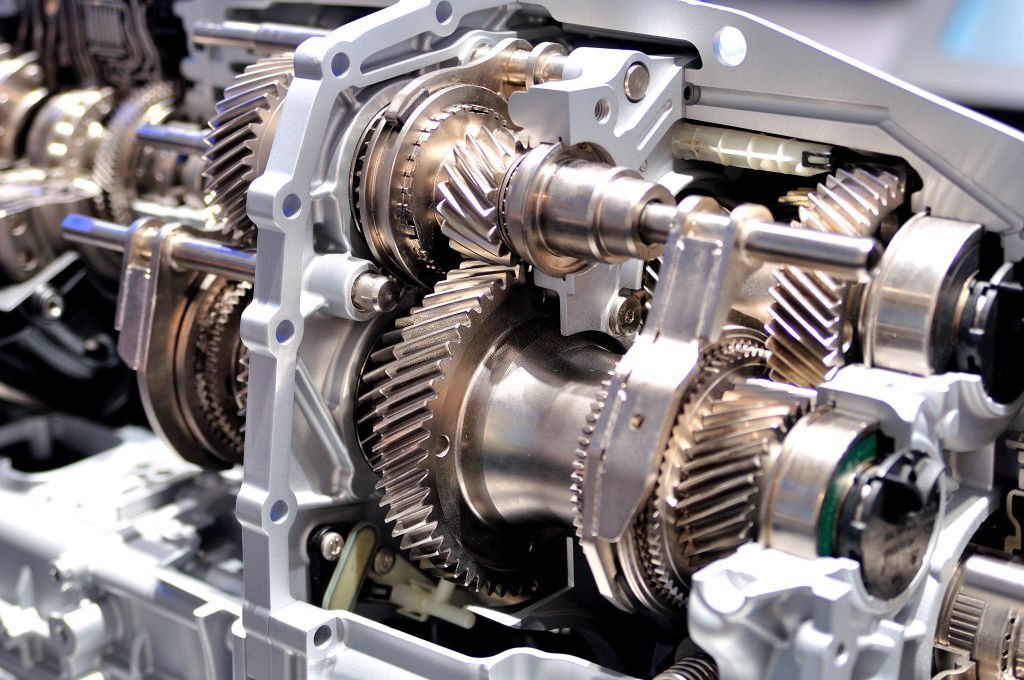

3. Speed and Gear Ratio Considerations

Matching the speed output of your gearbox with the speed requirements of your roller table is essential for maintaining control and efficiency.

Matching gearbox speed to roller table requirements: A mismatch in speed can cause jerky motion, increased wear, and decreased production efficiency. Gearboxes must be selected to deliver the ideal output speed based on the specific task.

Importance of adjustable speed ratios: In dynamic environments, gearboxes that offer variable speed ratios can adapt to multiple production needs. This flexibility is especially valuable in multi-functional manufacturing units.

4. Durability and Material Selection

Industrial gearboxes for roller tables must be constructed with durability in mind to withstand continuous heavy-duty use.

Robust construction for heavy-duty operations: Look for gearboxes made from high-grade alloy steel or ductile iron housing that can handle mechanical shocks and vibrations without cracking or warping.

Corrosion-resistant materials for longevity: In industries like metal processing or mining, where exposure to moisture, chemicals, or abrasive materials is common, corrosion resistance is key. Coated finishes and stainless steel components help extend operational life.

5. Thermal Performance and Heat Dissipation

Prolonged operations generate heat, and improper thermal management can result in gearbox failure.

Managing temperature rise during continuous operation: Heat buildup can degrade lubricant properties and affect gear alignment. Ensure your gearbox is rated for thermal performance aligned with your duty cycle.

Cooling methods and lubrication systems: Advanced industrial gearboxes include integrated cooling fins, forced air cooling, or external heat exchangers. Premium lubrication systems also maintain oil viscosity, reducing friction and wear.

6. Maintenance and Serviceability

Minimising downtime through easy maintenance is a major factor for operations managers.

Ease of installation and maintenance: Choose gearboxes that offer modular designs, easy access points, and standardised mounting interfaces. This allows for faster installation and minimal disruption during repairs.

Availability of spare parts and repair options: Partnering with experienced gearbox dealers ensures that spare parts are readily available. Santram Engineers provides prompt support, reducing lead time for part replacement and service.

7. Environmental and Operational Conditions

Finally, industrial gearboxes must be tailored to withstand the unique challenges of their working environment.

Performance in extreme temperatures and harsh environments: For outdoor or furnace-adjacent applications, ensure the gearbox can operate in extreme heat or cold without failure.

Considerations for dust, moisture, and chemical exposure: Gearboxes should include features such as sealed housings, IP-rated protection, and special coatings. These prevent ingress of contaminants, which could otherwise compromise performance.

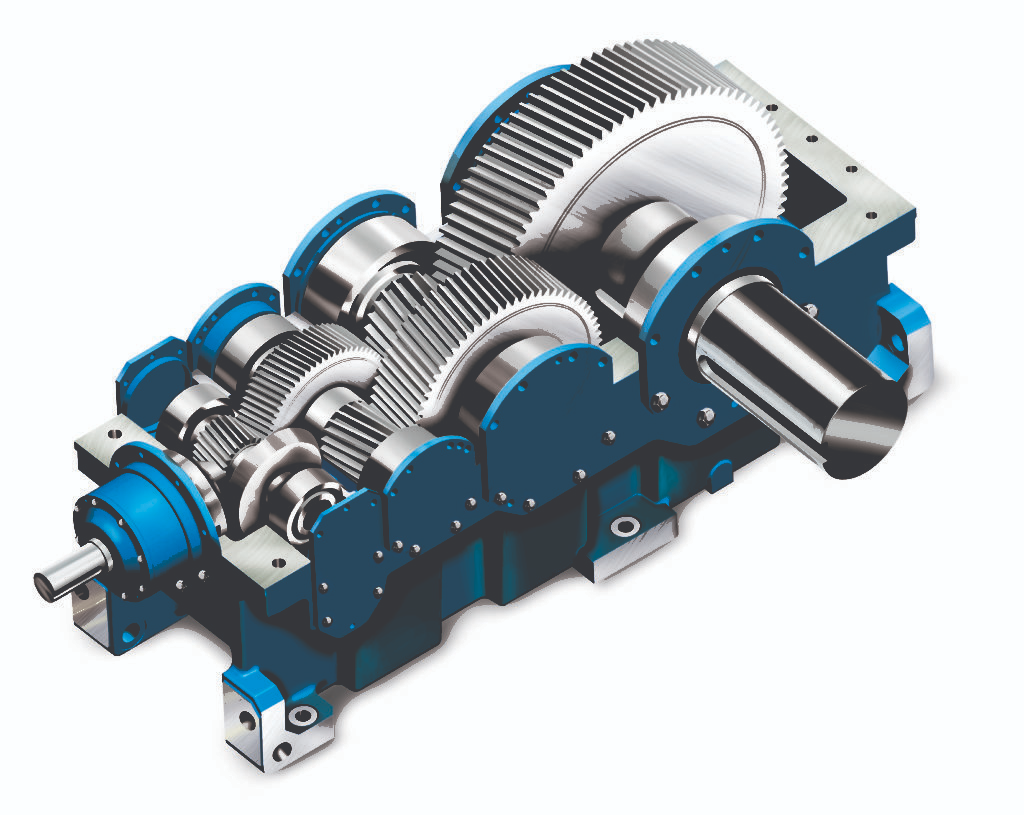

Comparing Different Types of Gearboxes for Roller Tables

Selecting the right industrial gearbox often involves comparing various types based on efficiency, torque output, and operational needs. For roller tables, where load control and smooth motion are essential, understanding the differences between gearbox types is key.

Helical vs. Worm Gearboxes

Helical gearboxes are known for their high efficiency and smooth power transmission. Their angled gear teeth provide superior torque output and minimal noise, making them ideal for roller tables in high-speed or continuous-duty operations. On the other hand, worm gearboxes offer compact design and high shock-load resistance, but generally at lower efficiency. They are better suited for applications where space is limited and occasional use is expected.

Planetary vs. Bevel Gearboxes

Planetary gearboxes are compact, deliver high torque density, and offer excellent performance in space-constrained environments. They are suitable for roller tables that require high speed reduction and power in a compact unit. In contrast, bevel gearboxes are ideal for applications needing angular direction changes and high precision in load distribution.

Each type brings specific benefits, and the choice depends on the layout, torque needs, and desired motion control of your roller table system.

Parallel Shaft vs. Right Angle Gearboxes

Parallel shaft gearboxes are designed with input and output shafts aligned in parallel, allowing for efficient power transmission and compact horizontal installation. These gearboxes are ideal for roller tables where space along the axis of motion is available and straightforward torque transfer is required. In contrast, right angle gearboxes change the direction of the shaft by 90 degrees, offering more flexibility in tight spaces or complex layouts. They are suitable for roller tables where installation constraints demand an angular drive setup without compromising on torque performance.

Industry Standards and Compliance

In industrial applications, adherence to recognised standards is non-negotiable. When selecting an industrial gearbox for roller table systems, it’s essential to ensure the product aligns with international benchmarks such as ISO (International Organisation for Standardisation) and AGMA (American Gear Manufacturers Association) standards. These regulations govern aspects like design accuracy, material quality, load handling, safety, and noise levels.

Gearboxes that comply with such standards are more reliable, efficient, and safer to operate in high-stress environments.

Optimise Your Roller Table Performance – Get Your Industrial Gearbox Today!

Your roller table system is only as strong as the gearbox that drives it. Don’t let subpar components slow down your operations or increase maintenance costs. At Santram Engineers, we specialise in delivering high-performance industrial gearboxes engineered for precision, durability, and efficiency—perfect for the demanding environments of steel plants, automotive assembly lines, and material handling systems.

Whether you’re upgrading an existing system or setting up a new production line, our expert team will help you choose the right gearbox tailored to your load, speed, and environmental requirements. As one of the leading gearbox dealers in Kerala, Chennai, Delhi, Tamil Nadu, and Odisha, among other regions, we offer unmatched support, prompt delivery, and long-term reliability.

Connect with Santram Engineers today and power your unique applications with the strength they deserve. Contact us at +91 96247 39393 or drop us a mail at sales@santramengineers.com to get started!