When it comes to industrial gearboxes, choosing between inline-geared motors and worm-geared motors can have a big impact on the efficiency and performance of various applications. It’s important for businesses to have a good understanding of the unique features, advantages, and uses of these two types of geared motors. This knowledge is crucial for making informed decisions when it comes to mechanical power transmission.

What is a Gear Motor?

At its core, a geared motor is an integrated unit that harmoniously combines an electric motor and a gearbox, creating a dynamic duo designed to deliver augmented torque and precise speed control. This synergistic combination finds application across industries where reliable power transmission is paramount.

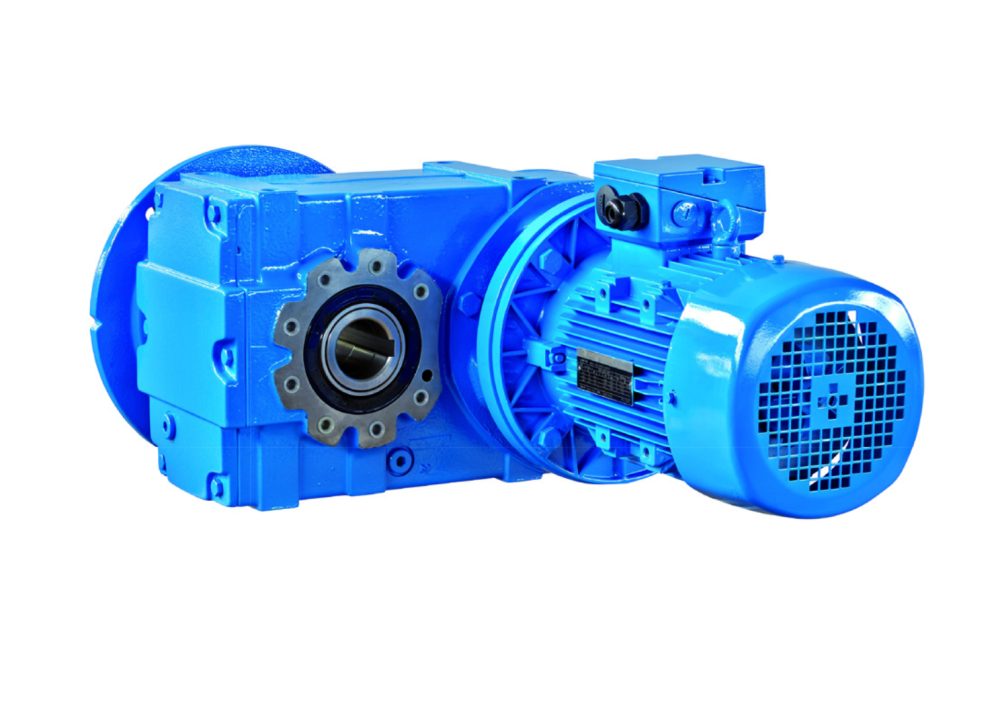

Helical Inline Geared Motors

Features

Inline geared motors boast a range of distinctive features that set them apart:

- Parallel Shaft Arrangement: One of the defining characteristics of these motors is their similar shaft arrangement, wherein the input and output shafts run parallel to each other. This arrangement facilitates streamlined power transmission and installation flexibility.

- Helical Gearing Mastery: Helical gears are a hallmark of helical inline-geared motors. These gears contribute to a higher degree of efficiency and smoother operation by minimizing noise and vibrations, enhancing the overall performance of the motor.

- Space Optimization: These motors are celebrated for their compact design. The space-saving attribute renders them ideal for applications with spatial constraints, allowing seamless integration into various setups.

Advantages

The advantages associated with helical inline geared motors encompass a broad spectrum of operational efficiencies:

- Elevated Efficiency: The deployment of helical gears within these motors contributes to heightened efficiency. This results in improved energy conversion and a reduction in power losses, making them an economically sound choice.

- Quiet Operation: The design enhances efficiency and ensures a smoother and quieter operation. This characteristic is particularly advantageous in applications where noise levels must be minimised.

- Versatility Personified: The motors exhibit remarkable versatility. Their adaptability renders them suitable for deployment across diverse industrial applications, ranging from conveyors to mixers and extruders.

Applications

The versatile nature of inline geared motors makes them indispensable in various industries:

- Material Handling: Conveyors, lifts, and hoists benefit substantially from the compact design and precise control facilitated by the helical geared motors. Their efficiency in material handling applications is unparalleled.

- Processing Machinery: The efficient power transmission and compact design make them a staple in mixers, extruders, and other processing equipment. The precise control they offer is invaluable in the manufacturing realm.

- Automation: The adaptability of the motors makes them a preferred choice in automated systems. Their precision and controlled movements contribute to the seamless functioning of automated processes.

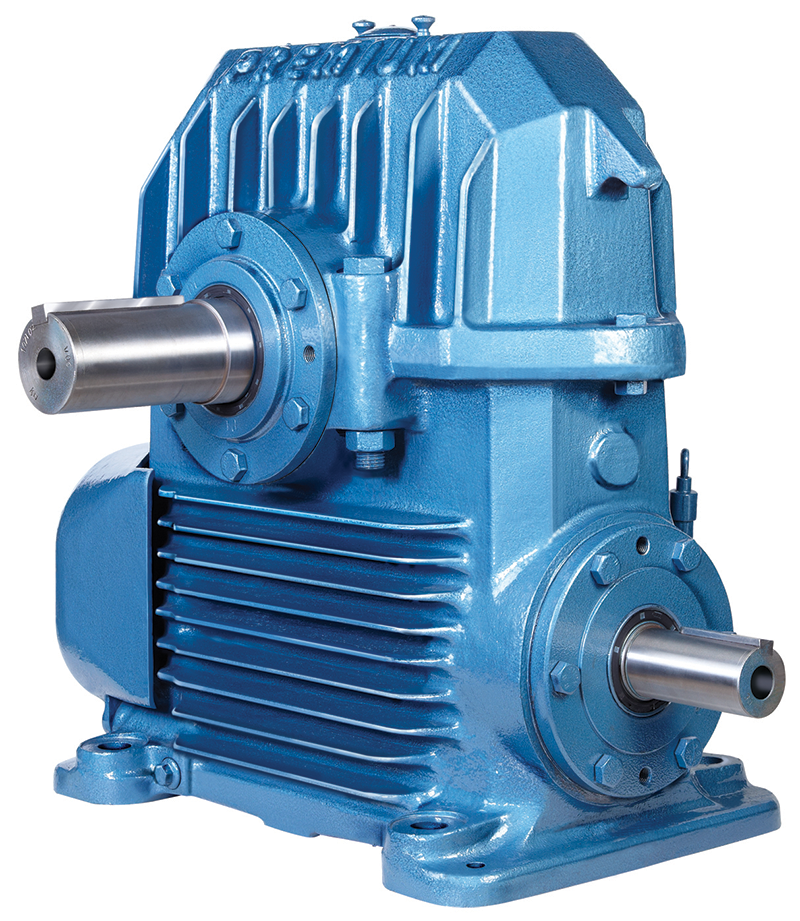

Worm-Geared Motors

Features

Worm-geared motors exhibit a distinct set of features that distinguish them:

- Worm and Worm Wheel Dynamics: At the heart of these motors lies the symbiotic relationship between a worm screw and a worm wheel. This configuration results in a right-angle drive that defines the motor’s operational essence.

- Gearing Down: Worm gears inherently provide a high gear reduction ratio, making the motors the preferred choice for applications demanding low-speed and high-torque outputs.

- Self-Locking Mastery: A notable feature of these motors is their self-locking property. This inherent characteristic prevents back-driving, enhancing the motor’s holding capacity and reliability.

Advantages

Worm-geared motors present a unique set of advantages that cater to specific industrial needs:

- Torque at Low Speeds: The design of these motors makes them exceptionally adept at generating high torque at low speeds. This characteristic is especially advantageous in applications such as conveyor systems and winches.

- Cost-Effective: The motors often emerge as the more cost-effective option compared to their counterparts. This affordability factor makes them a preferred choice for applications where budget considerations play a significant role.

- Space-Saving: The right-angle drive configuration of the motors inherently translates into a space-saving design. This characteristic is particularly valuable in installations where spatial constraints dictate equipment choices.

Applications

The unique attributes of worm-geared motors make them indispensable in various industrial settings:

- Material Handling: Conveyor systems, winches, and lifting equipment extensively leverage the high torque output of the motors at low speeds. Their reliability in these applications is unparalleled.

- Industrial Machinery Mainstay: Applications in industrial machinery, such as packaging machines, printing presses, and rolling mills, frequently rely on geared motors. Their cost-effectiveness and reliability make them a mainstay in such equipment.

- Outdoor Operational: The self-locking feature of the motors makes them particularly suitable for outdoor applications. In scenarios where holding the load is crucial, these motors emerge as a reliable choice.

Difference Between Inline Geared Motors and Worm Geared Motors

To facilitate a clearer comparison, let’s break down the distinctions in a comprehensive chart:

| Feature | Inline Geared Motors | Worm Geared Motors |

| Shaft Arrangement | Parallel Shaft Arrangement | Right-Angle Drive Configuration (Worm Screw) |

| Gearing Mechanism | Helical Gears | Worm Screw and Worm Wheel |

| Efficiency | Higher efficiency due to helical gears | Slightly lower efficiency due to worm gears |

| Noise and Vibration | Lower noise and vibration levels | Moderate noise and vibration levels |

| Torque at Low Speeds | Moderate torque at low speeds | High torque at low speeds |

| Back-Driving Prevention | Not inherently self-locking | Inherently self-locking |

| Cost | Generally higher cost | Generally more cost-effective |

| Space Utilization | Compact design, suitable for limited space | Compact design, ideal for space-constrained setups |

Considerations When Making Purchase Decision

The decision-making process for industrial gearbox operators involves a careful consideration of several factors. When choosing between inline-geared and worm-geared motors, the following considerations come into play:

1. Application Requirements

The specific requirements of the application should guide the choice between both motors. For applications demanding precise control, smooth operation, and versatility, inline geared motors with helical gears may be the optimal choice. On the other hand, if the application requires high torque at low speeds and self-locking capabilities, worm-geared motors are better suited.

2. Noise Sensitivity

Noise levels can be a critical factor, especially in applications where a quiet operational environment is imperative. With their helical gears, inline geared motors offer lower noise and vibration levels, making them suitable for scenarios where noise reduction is a priority.

3. Torque and Speed Requirements

Understanding the specific torque and speed requirements of the application is crucial. Inline counterparts are well-suited if the application demands moderate torque at varying speeds. However, if high torque at low speeds is essential, worm-geared ones excel in delivering the required performance.

4. Back-Driving Concerns

In applications where preventing back-driving is crucial, worm-geared motors, with their inherently self-locking feature, provide a distinct advantage. This property enhances the holding capacity of the motor, making it suitable for scenarios where the load needs to be held securely.

5. Space Constraints

The spatial limitations of the installation site play a crucial role in determining the choice between inline-geared and worm-geared motors. The compact design of both types makes them suitable for applications with space constraints. However, the right-angle drive configuration of these motors can be particularly advantageous in situations where a compact design is essential.

Cost Considerations

While the initial cost is a significant factor, a holistic view of the long-term operational costs should also be taken into account.

Initial Investment:

- Inline Geared Motors: These motors generally come with a higher initial investment due to the use of helical gears and their associated manufacturing processes.

- Worm-Geared Motors: Known for their cost-effectiveness, the motors often have a lower initial cost, making them an attractive choice for businesses with budget constraints.

Long-Term Operational Costs:

- Inline Geared Motors: Despite the higher upfront cost, the efficiency and reduced power losses associated with helical gears can contribute to lower energy consumption and, consequently, operational cost savings over the motor’s lifespan.

- Worm-Geared Motors: While more economical initially, they may exhibit slightly higher energy consumption. However, their cost-effectiveness can still make them an attractive choice for specific applications.

Maintenance Costs:

- Inline Geared Motors: The design of helical gears often results in smoother operation and reduced wear and tear, leading to lower maintenance costs over time.

- Worm-Geared Motors: The self-locking feature inherent in the motors can reduce the occurrence of wear, contributing to lower maintenance costs. However, periodic lubrication is crucial to ensure optimal performance.

FAQs about the Gear Motors

1. What distinguishes the shaft arrangements of both types of gear motors?

Inline-geared motors feature a parallel shaft arrangement, while worm-geared ones utilise a right-angle drive configuration with a worm screw and worm wheel.

2. How do helical gears in inline geared motors contribute to efficiency?

Helical gears enhance efficiency by reducing noise and vibrations, resulting in smoother operation and improved energy conversion.

3. What is the self-locking feature in worm-geared motors, and how does it impact applications?

The self-locking property of worm gears prevents back-driving, enhancing the holding capacity. This feature is crucial in applications where load retention is paramount.

4. What considerations should businesses prioritise when choosing between these geared motors?

Businesses should consider application requirements, noise sensitivity, torque and speed needs, back-driving concerns, and cost considerations to make an informed decision aligned with their operational goals and budget constraints.

We Offer a Wide Range of Gear Motors

Explore a wide range of high-performance gear motors at Santram Engineers and take your projects to new heights. Our collection of industrial gearboxes and motors is tailored to meet your unique needs, whether you require precision, power, or efficiency.

The products we supply are engineered by the leading name Premium Transmission, providing seamless integration, enhanced durability, and unmatched reliability. Elevate your machinery, automation, and robotics with the perfect gear motor from our collection.

Browse our catalogue now to discover the driving force behind countless industries. Unleash the potential of your applications with Santram Engineers. Your journey to superior performance starts here. Gear up for success and transform your vision into motion with our wide range of gear motors. Shop now!

Reach out to us at +91 96247 39393 or mail us at sales@santramengineers.com for any queries you may have related to our products and services. We will be happy to assist you.