Selecting the right gearbox for your conveyor system is essential to ensure efficient performance, reliability, and cost-effectiveness. A conveyor system is the backbone of many industrial operations, and the gearbox plays a vital role in ensuring smooth and controlled movement. The wrong choice can lead to costly breakdowns, inefficiencies, or even safety issues. In this guide, we explore the critical factors to consider when choosing a gearbox for a conveyor system. We will also provide insight into conveyor gearbox pricing in India and highlighting Premium Transmission Limited as a trusted provider.

The Role of a Gearbox in Conveyor Systems

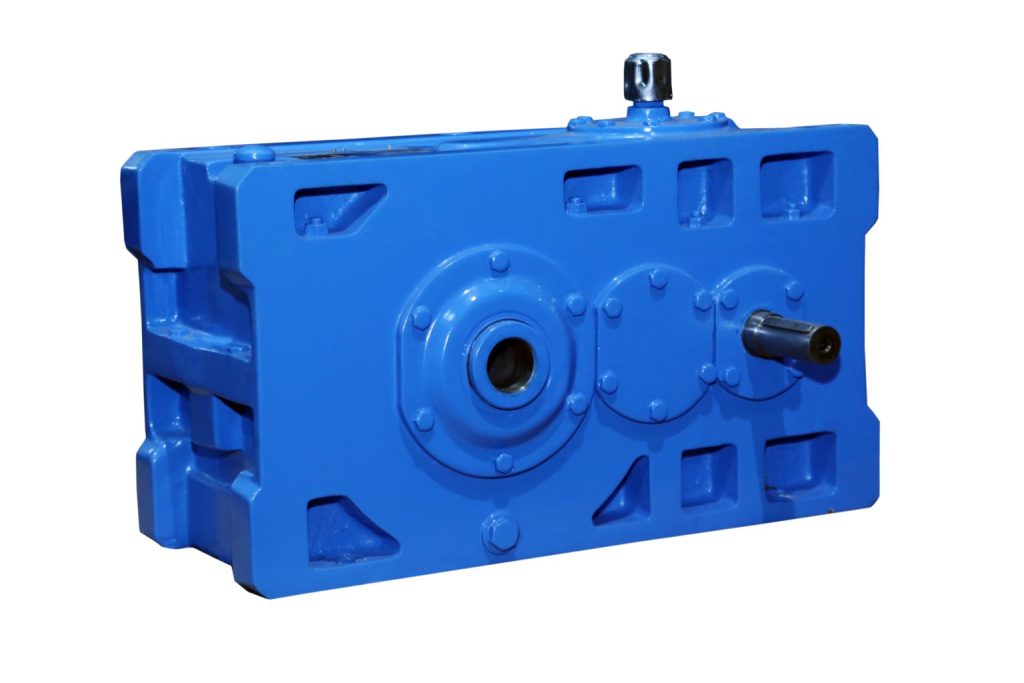

A gearbox in a conveyor system serves as a power transmission component, controlling speed and torque. It helps convert the high-speed input from a motor into the slower speed needed to drive the conveyor. The gearbox also ensures the right amount of torque is applied to move heavy loads efficiently without putting undue strain on the system. This balance is crucial, as it affects the operational efficiency and longevity of the conveyor. Premium Transmission Limited, a leading name in industrial gear solutions, offers reliable gearboxes designed for various conveyor applications, ensuring smooth and efficient operation.

Key Factors to Consider When Choosing a Gearbox for Conveyor

Load Capacity and Torque Requirements

Understanding your conveyor system’s load capacity and torque requirements is the first step in selecting the appropriate gearbox. The gearbox must be able to handle the maximum load without overloading. Choosing a gearbox with the right torque ensures the system operates efficiently without unnecessary wear. Too little torque can lead to performance issues, while excessive torque may increase energy consumption and reduce the life of the system. When considering the conveyor gearbox price in India, balancing cost with performance is key to achieving long-term operational efficiency.

Operating Conditions

The environmental conditions in which the conveyor operates play a crucial role in gearbox selection. Factors like temperature, humidity, dust, and exposure to corrosive materials can impact the performance and longevity of a gearbox. For example, if your conveyor operates in a high-temperature environment, you’ll need a gearbox that can handle heat without compromising efficiency. Similarly, gearboxes exposed to harsh or corrosive environments may require special coatings or seals to prevent damage. Premium Transmission Limited offers a range of gearboxes designed to withstand diverse operating conditions, ensuring durability and optimal performance.

Speed and Gear Ratio

The required speed of your conveyor and the gear ratio of the gearbox are closely linked. A high gear ratio will result in slower conveyor speed but higher torque, while a low gear ratio will provide faster speeds with lower torque. Depending on the application—whether moving heavy materials or high-speed sorting—choosing the right speed and gear ratio is essential. Ensuring the correct balance between speed and torque improves productivity and reduces the likelihood of mechanical stress on the conveyor system.

Types of Gearboxes Suitable for Conveyors

Selecting the right type of gearbox for your conveyor system is crucial for ensuring optimal performance, efficiency, and longevity. Each type of gearbox offers unique benefits and is suited to specific applications. Below, we explore the most common types of gearboxes used in conveyor systems and their respective advantages.

Helical Gearbox

A helical gearbox is one of the most commonly used gearboxes in conveyor systems due to its efficiency and smooth power transmission. The teeth of helical gears are cut at an angle, which allows them to engage more gradually compared to spur gears. This design reduces noise and vibration while providing higher load-carrying capacity.

Benefits and Applications:

- Excellent for conveyors that require continuous and smooth operation.

- High efficiency, making it suitable for energy-conscious businesses.

- Used in various industries like food processing, material handling, and packaging.

- Its efficiency and quiet operation make it ideal for longer conveyor systems.

Premium Transmission Limited offers high-quality helical gearboxes that are known for their durability and low maintenance needs, making them a reliable choice for conveyor applications.

Worm Gearbox

A worm gearbox features a worm gear meshing with a worm wheel, which allows for a high reduction ratio in a compact design. However, they are generally less efficient than helical or bevel gearboxes due to higher friction.

Features, Pros, and Cons:

- Compact and cost-effective, making it a good option where space is limited.

- High reduction ratios with fewer components.

- Lower efficiency and higher heat generation compared to other types.

- Ideal for conveyors with low-speed, high-torque requirements.

Worm gearboxes are often chosen when budget constraints are a priority. However, the price can vary depending on the model and specifications.

Bevel Helical Gearbox

The bevel helical gearbox is designed for heavy-duty applications, making it ideal for conveyors that handle large loads or operate under harsh conditions. This type of gearbox combines the advantages of bevel gears and helical gears, providing both high efficiency and strength.

Best Uses for Heavy-Duty Applications:

- Suitable for mining, quarrying, and heavy manufacturing.

- High torque transmission capability.

- Long-lasting and durable, reducing maintenance costs over time.

Planetary Gearbox

A planetary gearbox is highly efficient and compact, making it suitable for specialized applications where space is a premium, and high torque is required.

Benefits and Applications:

- Best suited for conveyors with high-precision requirements.

- Frequently used in automation, robotics, and complex material handling systems.

- Provides high efficiency and compactness for space-constrained applications.

Businesses can rely on Premium Transmission Limited for a variety of gearbox solutions, including planetary gearboxes, ensuring optimal performance for their conveyor systems.

Comparison Chart Highlighting Advantages and Disadvantages of Each Type

| Gearbox Type | Advantages | Disadvantages |

| Helical Gearbox | High efficiency, smooth operation, suitable for long conveyors | Higher initial cost compared to worm gearboxes |

| Worm Gearbox | Compact, cost-effective, high reduction ratio | Lower efficiency, higher heat generation, more wear |

| Bevel Helical Gearbox | High torque capacity, ideal for heavy-duty applications | Larger size, higher cost |

| Planetary Gearbox | Compact, high precision, ideal for high-torque applications | Complex design, higher cost |

This comparison helps businesses evaluate different gearbox options and balance performance, cost, and suitability for their conveyor systems.

Importance of Efficiency and Energy Savings

Selecting the right gearbox for conveyor systems is not just about performance. It directly affects energy consumption and overall operational costs. An efficient conveyor gearbox reduces energy loss during transmission, resulting in significant energy savings over time. This can lower operational costs, especially in systems that run continuously. With the rising cost of energy, improving efficiency is a top priority for many businesses.

Premium Transmission Limited offers advanced gearbox designs that focus on energy efficiency, minimizing friction and heat loss. These modern gearboxes feature high-quality components, such as precision-cut gears and advanced lubrication systems, that enhance performance while reducing energy waste.

The impact of an efficient gearbox goes beyond energy savings. It also extends the life of the conveyor system by reducing wear and tear on both the gearbox and motor. This minimizes maintenance costs, downtime, and ultimately the total cost of ownership.

Advanced features to look for include automatic lubrication, variable speed control, and optimized gear geometry. These features ensure smoother operation and further improve energy efficiency, making a significant difference in long-term cost savings and productivity.

Frequently Asked Questions

1. What is the function of a gearbox in a conveyor system?

A gearbox for conveyor systems plays a critical role in converting the speed and torque of the motor into the optimal levels required for operation. It helps regulate the speed and direction of the conveyor while providing the necessary torque to move materials efficiently. Without a properly selected gearbox, the conveyor may operate inefficiently, leading to potential mechanical failure or reduced productivity. A reliable gearbox ensures smooth operation, reduces strain on the motor, and minimizes energy consumption.

2. How do I determine the correct size of a gearbox for my conveyor?

Choosing the correct size of a conveyor gearbox involves calculating key parameters like load capacity, torque, and speed. Begin by identifying the maximum load the conveyor will need to move and the required torque to handle that load. Additionally, the speed of the conveyor and the motor power should be factored in. Consulting with experts such as Santram Engineers which offers a range of gearbox solutions from Premium Transmission Limited, can help ensure you select the right size and type of gearbox for your specific application. Undersizing or oversizing the gearbox can lead to inefficiencies or increased maintenance costs.

3. How does the gear ratio affect conveyor performance?

The gear ratio directly impacts the speed and torque of your conveyor system. A higher gear ratio will reduce the speed but increase torque, which is essential for moving heavier loads. On the other hand, a lower gear ratio provides faster speeds but less torque, making it ideal for lighter or faster-moving materials. Balancing speed and torque is essential for optimizing the performance and longevity of your conveyor. A properly selected gear ratio ensures the conveyor operates efficiently, reducing energy consumption and wear on the system.

4. Can gearboxes be customized for specific conveyor applications?

Yes, gearboxes can be customized to meet the specific needs of your conveyor system. Premium Transmission Limited offers customization options for gearboxes, including specialized gear ratios, mounting positions, and materials to withstand harsh environmental conditions. This ensures your gearbox is optimized for your unique application, whether it’s a high-torque, low-speed conveyor in a mining operation or a high-speed, light-duty conveyor in a packaging plant.

5. What is the expected lifespan of a gearbox used in conveyors?

The lifespan of a gearbox for conveyor systems depends on factors like operating conditions, maintenance, and usage intensity. With regular maintenance, a high-quality gearbox from suppliers like Santram Engineers can last anywhere from 10 to 20 years. Proper lubrication, avoiding overloading, and choosing the right gearbox type for your application can significantly extend its operational life.

Get Expert Guidance on Choosing the Right Gearbox for Your Conveyor Today!

Selecting the right gearbox for your conveyor is essential to ensure efficient operation, minimize downtime, and reduce long-term costs. Santram Engineers is the largest distributor and supplier for Premium Transmission Limited, one of the leading gearbox manufacturing companies in India.

We specialize in providing tailored gearbox solutions that meet the unique demands of your conveyor systems. Whether you need a high-torque gearbox for heavy loads or a high-speed option for lighter tasks, our team of experts is here to guide you through the selection process.

With our industry-leading expertise and a wide range of industrial gearbox options, we can help you boost efficiency and reliability. Reach out to us at +91-96247 39393 or write to us at sales@santramengineers.com to get the right gearbox for your system and enjoy long-term operational benefits. Talk to our specialists now and optimize your conveyor performance!