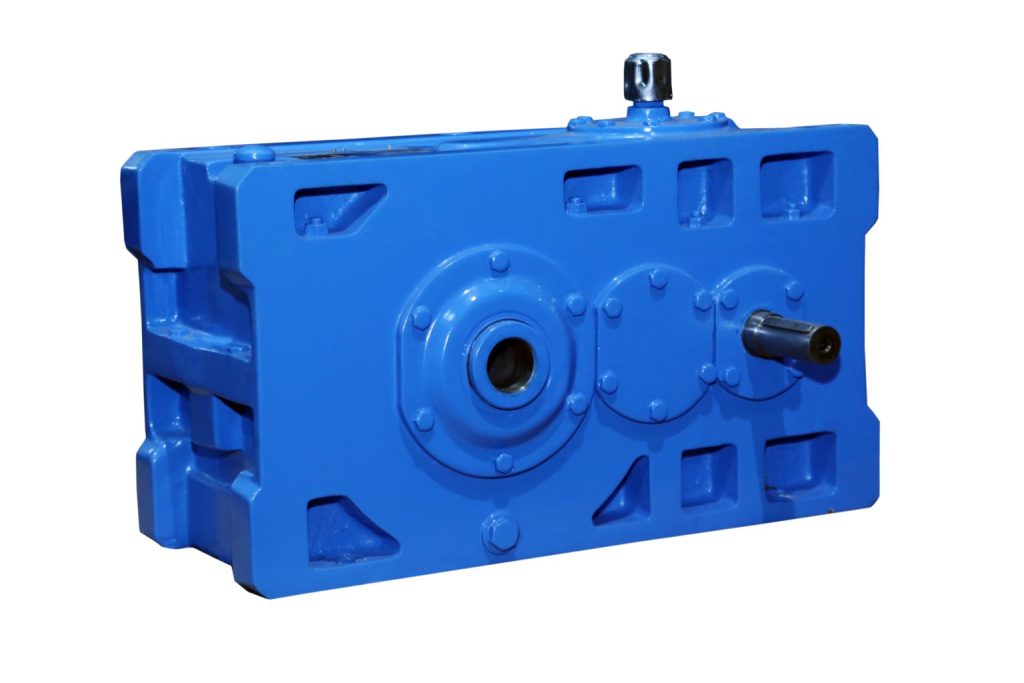

Industrial gearboxes play a far more important role in a production unit than it appears. A malfunction in the gearbox will not only halt operations but can even bring the entire plant to a grinding halt. Hence adequate care must be taken to prevent any malfunctions in the functioning of a gearbox. Here’s a list of some of the things that you can take care of to ensure that your business remains safe from such malfunctions.

12 Tips to Increase the Life of an Industrial Gearbox Before Installation of Gearbox

1. Check for Operating Recommendations

The first thing that you must check for before installing the industrial gearbox is to check if it is operating as per the specifications provided by the manufacturer. Often, gearboxes are put into applications that are greater than their permitted standard, which results in malfunctions.

2. Ensure Proper Lubrication

This is a vital step. Before you install the industrial gearbox, you need to ensure that it is provided with proper lubrication as per the specifications provided by the manufacturer. Also, do not forget to use oil cups if you are using a vertical gearbox.

3. Clean Surfaces Before Joining the Gearbox and Motor

Do make sure that before you join the gearbox and the motor, make sure the surfaces that will join them are clear of any kind of rust. The manufacturer will provide you with rust preventive. Use this to keep your industrial gearbox in good condition for a long time.

4. Ensure the Size of the Coupling is As Per the Specifications

Follow the instruction manual to ensure the size of the coupling is as per specification.

5. Check Each Parameter

Before you connect the gear-fitted motor to the load, do check out for noise, vibration, leakage and temperature of the industrial gearbox.

6. Use Stoppers for Foot-Free Gearboxes

Install stoppers when using foot-free industrial gearboxes. The stoppers will prevent the gearbox and motor from changing their original position.

7. Try Tyre Coupling

When using foot-free gearboxes, try using tyre coupling. The flexibility of tyre couplings can compensate for significant angle errors and can reduce vibration and impact to a great extent.

8. After Installation & Commissioning of Gearboxes

Regular maintenance can keep your industrial gearbox in the best condition for a long time. So once you have installed and commissioned the gearbox, here are a few things that you can do to keep your gearbox in better condition.

9. Change the Lubricant Oil Regularly

Check the manufacturer’s specifications for oiling. Change the lubricant oil after the specified number of hours. Also, observe the old oil and look for metallic particles that can indicate wear and tear of internal parts.

10. Check for Noise and Vibration

Note noise and vibrations in the industrial gearbox. A regular vibration and noise check can help you analyse the internal condition of the gearbox.

11. Monitor Temperature Regularly

Check for signs of overheating in the industrial gearbox. Burnt paint on the exterior or dark oil or discolouration can indicate overheating of the gearbox. You can even use an infrared temperature gun to keep a track of the temperature of the industrial gearbox.

12. Consult the Manufacturer for Advice or Support

As much as you would be tempted to call in a local technician to fix issues in the gearbox, the best thing that you can do is consult the manufacturer. Stick to the specifications and reach out to the manufacturer when you experience malfunctions in the industrial gearbox.

Reach Out for All Your Queries Regarding Gearboxes

Santram Engineers have decades of experience in helical gearboxes and Power Transmission Products. The company is the largest distributor and stockiest for Premium Transmission Limited.

For any queries related to gearboxes and buying gearboxes online, you can reach out to our experts for consultation by calling us at +91-96247 39393 or writing to us at sales@santramengineers.com. We would be happy to help!