When it comes to operating overhead cranes, selecting the right gearbox is critical. A properly chosen gearbox ensures efficient performance, long-term reliability, and safety in industrial environments. Overhead cranes operate under demanding conditions, such as heavy loads and continuous use, making the gearbox a crucial component of the entire system. Businesses must consider several technical and operational factors to ensure the gearbox matches the crane’s requirements. They must also choose the right gearbox manufacturer to ensure quality, precision engineering, and ongoing support for maintenance and repairs.

As one of the leading industrial gearbox suppliers, we have compiled this guide to help understand essential aspects to keep in mind when selecting a gearbox for overhead cranes.

Understand the Application Requirements

Overhead cranes perform three primary motions: Long Travel (LT), Cross Travel (CT), and Hoisting. Each function has distinct demands that your gearbox must meet.

Long Travel (LT): Speed, Torque, and Load-Handling Capacity

Long Travel involves the movement of the crane along the runway. The gearbox must provide sufficient torque and speed to ensure smooth, efficient movement. It should also handle the weight of the crane structure and its maximum load capacity. High precision and power transmission efficiency are essential to avoid delays and mechanical strain during operation.

Cross Travel (CT): Compact Design and Smooth Operation

Cross Travel refers to the horizontal movement of the hoist or trolley across the crane’s width. Gearboxes for CT applications need a compact and lightweight design, as they often operate in space-constrained areas. Smooth operation is vital to prevent jerky movements, which can lead to wear and tear or damage to the load being handled.

Hoisting: High Torque and Safety Considerations

Hoisting involves lifting and lowering loads, making it the most critical motion for overhead cranes. Selecting the right gearbox manufacturer ensures the gearboxes used for hoisting must deliver high torque to handle heavy loads while incorporating safety features like braking systems and load-holding capabilities. Any failure in this application can lead to catastrophic consequences, so reliability and durability are paramount.

Load Capacity and Duty Cycle

Maximum Load and Average Load Handling

Before selecting a gearbox, it is essential to determine the maximum and average load the crane will handle. The gearbox should be capable of managing the peak loads without excessive strain while efficiently handling routine operations. Miscalculating load capacity can lead to premature failure or inefficient energy use.

Duty Classification: Heavy-Duty, Medium-Duty, or Light-Duty Applications

The crane’s duty cycle significantly impacts the gearbox selection process. Heavy-duty applications involve frequent starts and stops, continuous operation, and handling extremely heavy loads. Medium-duty gearboxes are suitable for moderate workloads, while light-duty gearboxes are designed for occasional or less demanding usage. Understanding your operational needs helps in choosing a gearbox that matches your requirements, ensuring long service life and cost efficiency.

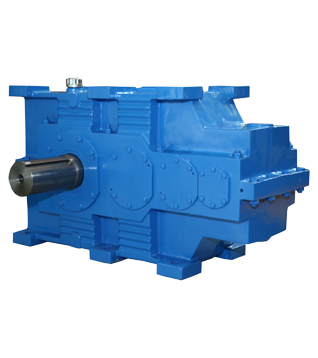

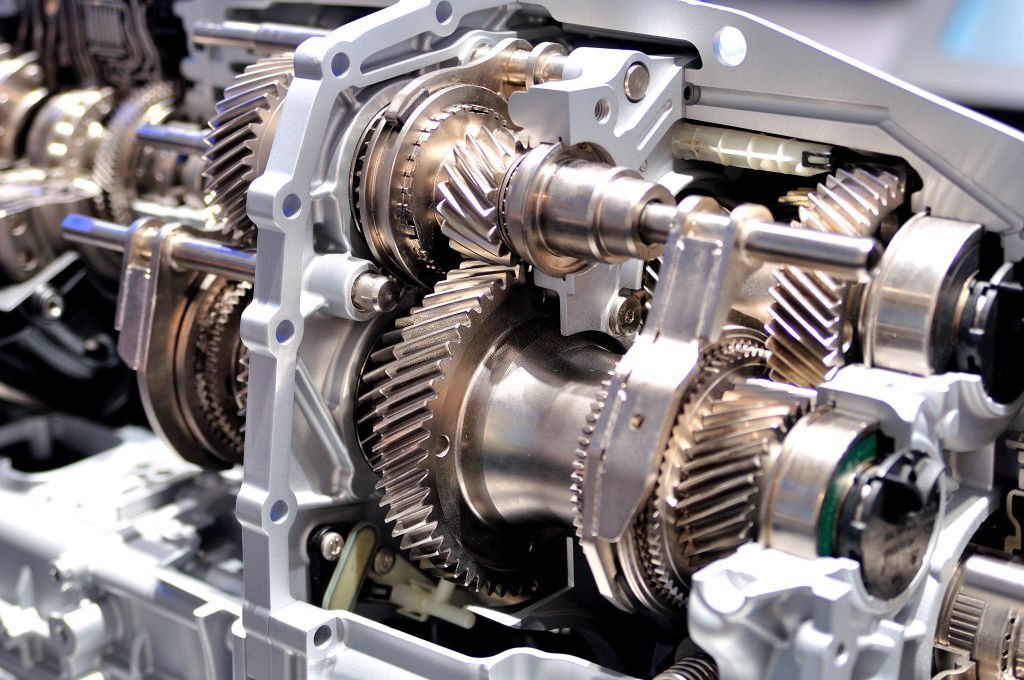

Gearbox Type and Design

Helical, Bevel, or Planetary Gears for Optimal Efficiency

Different gearbox designs serve varying functions. Helical gears offer smooth and quiet operation, making them ideal for high-speed applications. Bevel gears are suitable for angular movement and compact spaces. Whereas planetary gears are known for their high torque capacity and efficiency.

Choosing the right gear type ensures that your gearbox meets the specific demands of your crane’s application. A gearbox manufacturer can provide expert guidance and customised solutions to ensure the gearbox design aligns perfectly with your crane’s operational needs.

Compact and Lightweight Design for Space-Constrained Areas

Modern industrial environments often require compact solutions. Gearboxes with lightweight and space-saving designs help optimise the crane’s overall structure and reduce installation complexity. Additionally, a well-designed gearbox enhances the system’s aesthetic and functional appeal while maintaining robust performance.

Speed and Torque Requirements

When selecting a gearbox for overhead cranes, understanding speed and torque requirements is crucial. These parameters directly influence the crane’s performance and operational efficiency.

Input and Output Speed Ratios

The gearbox’s input and output speed ratios determine how effectively power is transmitted from the motor to the crane’s movements. For Long Travel (LT) and Cross Travel (CT), the gearbox must achieve the right balance between speed and torque to ensure smooth, precise motion.

Hoisting applications, on the other hand, require lower speeds but higher torque for safely lifting and lowering loads. Matching the speed ratio to the crane’s operational needs ensures that the gearbox performs efficiently without unnecessary strain.

Torque Ratings for Various Crane Movements

Torque is critical for handling the loads involved in overhead crane operations. Each motion—long travel, cross travel, and hoisting—requires specific torque ratings. Gearboxes must provide adequate torque to handle the maximum load capacity without compromising performance or safety.

High torque ratings are particularly important for hoisting, where failure can lead to significant safety risks. Ensuring the gearbox meets the required torque specifications minimises wear and extends the system’s service life. Partnering with a reputable gearbox manufacturer ensures precision-engineered solutions that meet the required torque specifications.

Durability and Material Selection

The industrial environments where overhead cranes operate often involve exposure to harsh conditions. Choosing a durable and reliable gearbox is essential for maintaining performance and longevity.

High-Grade Materials for Wear and Corrosion Resistance

Gearboxes for overhead cranes should be made from high-grade materials such as hardened steel or cast iron. These materials provide excellent resistance to wear, ensuring the gearbox withstands continuous operation under heavy loads. For applications in corrosive environments, such as chemical plants or coastal areas, materials with corrosion-resistant properties are vital to prevent damage and maintain reliability.

Special Coatings for Harsh Environments

In some cases, standard materials may not be enough to withstand the operating environment. Special coatings, such as anti-corrosion or anti-abrasion finishes, can enhance the gearbox’s resilience. These coatings protect against moisture, chemicals, and abrasive particles, ensuring that the gearbox performs optimally even in extreme conditions.

Alignment with Crane Structure

Seamless integration with the crane’s design is another important consideration. A poorly aligned gearbox can lead to inefficiencies, increased wear, and operational issues.

Seamless Integration with Crane Beams and Mounting Options

The gearbox must align perfectly with the crane’s structure, including its beams and mounting configurations. A reliable gearbox manufacturer can provide customized mounting options to simplify installation and reduce the need for structural modifications. This not only saves time but also ensures better compatibility and operational stability.

Compatibility with the Existing Hoist or Trolley Setup

If you are retrofitting a gearbox onto an existing crane, it must be compatible with the hoist or trolley setup. Compatibility reduces installation challenges and ensures that the gearbox works harmoniously with other components of the crane.

Maintenance and Lubrication

Proper maintenance and lubrication are essential for minimising downtime and extending the gearbox’s lifespan.

Easy Accessibility for Inspection and Repairs

Gearboxes should be designed for easy accessibility, allowing technicians to perform regular inspections and repairs without extensive disassembly. Features such as inspection windows and external access points can significantly reduce maintenance time and effort.

Lubrication Systems for Minimal Downtime

Effective lubrication systems are critical for reducing friction and wear. A trusted gearbox manufacturer can integrate automatic or semi-automatic lubrication systems to enhance operational efficiency by ensuring consistent lubrication, even during continuous use. These systems minimize the need for manual intervention and reduce the likelihood of unexpected downtime due to lubrication issues.

Safety and Compliance Standards

When choosing a gearbox for overhead cranes, safety and compliance should be non-negotiable. Gearboxes play a vital role in maintaining the operational integrity of the crane, so they must adhere to rigorous safety norms and include essential protective features.

Adherence to International Safety Norms Like ISO and FEM

Ensure the gearbox complies with recognised standards like ISO (International Organisation for Standardisation) and FEM (Federation of European Material Handling). These regulations ensure the gearbox is designed and manufactured to meet stringent safety, quality, and performance criteria. Compliance reduces risks and ensures the equipment is suitable for industrial operations worldwide.

Features Like Overload Protection and Emergency Stop Mechanisms

Modern gearboxes often come equipped with safety features, such as overload protection and emergency stop mechanisms. A reliable gearbox manufacturer ensures these features are designed to safeguard the gearbox and crane by preventing excessive stress during operation, while emergency stop mechanisms enhance safety in case of system failure or unforeseen events. These features are essential for minimizing downtime and avoiding costly accidents.

Power Efficiency and Noise Levels

Operational efficiency and workplace comfort are also critical factors when selecting a gearbox for overhead cranes.

Energy-Efficient Designs to Reduce Operational Costs

Energy efficiency is a priority for businesses aiming to reduce operational costs and environmental impact. Look for gearboxes with optimised designs that minimise power loss and enhance transmission efficiency. Advanced technologies like high-precision gear machining and low-friction materials contribute to reduced energy consumption and long-term cost savings.

Low-Noise Performance for Better Workplace Conditions

Excessive noise can create an uncomfortable working environment and lead to compliance issues in noise-regulated industries. Gearboxes with low-noise operation help improve workplace conditions and meet regulatory requirements. Features such as helical gear designs and vibration-dampening technologies ensure smoother and quieter operation, which is particularly beneficial in indoor or noise-sensitive settings.

Customisation and Scalability

No two crane applications are identical, making customisation and scalability essential for optimal gearbox performance.

Custom-Built Options for Unique Crane Configurations

If your crane operates in a non-standard environment or has unique requirements, a custom-built gearbox may be the best solution. Gearbox manufacturers often offer customisation options, including specific mounting configurations, gear ratios, or materials, to match the crane’s design and operational needs. Customisation ensures seamless integration and peak performance for specialised applications.

Scalability to Accommodate Future Capacity Expansions

As your business grows, your overhead crane’s capacity requirements may increase. A scalable gearbox design allows for future upgrades without the need for complete replacement. For instance, modular designs enable easy adjustments to torque or speed capacities, ensuring the gearbox remains a valuable asset even as operational demands evolve.

Manufacturer Expertise and Support

The reliability and performance of a gearbox are directly tied to the expertise and support of its manufacturer.

Proven Track Record in the Crane Industry

Choose a gearbox manufacturer with a strong history of supplying gearboxes for overhead cranes. Their industry experience ensures they understand the specific demands of crane applications and provide solutions tailored to meet those needs. Look for testimonials, case studies, or certifications that validate their expertise.

Availability of Technical Support and After-Sales Service

Even the best gearboxes require maintenance and occasional repairs. A manufacturer that offers comprehensive technical support and after-sales service ensures you have access to expert assistance whenever needed. This includes installation guidance, troubleshooting, and quick access to spare parts to minimise downtime.

Contact Us for Expert Guidance on Selecting the Perfect Gearbox for Your Application!

Choosing the right gearbox for your overhead crane is critical for ensuring efficiency, safety, and long-term reliability. Don’t leave this important decision to chance—partner with experts who understand your unique needs. At Santram Engineers, we offer tailored guidance to help you find the perfect gearbox solution for your application.

Whether you’re upgrading an existing system or outfitting a new one, our team of industry specialists is ready to provide insights on load capacity, torque requirements, and compliance with international standards. With our extensive range of high-quality gearboxes and exceptional customer support, we ensure your operations run smoothly and efficiently.

Contact us at +91-96247 39393 or write to us at sales@santramengineers.com for expert advice, a seamless selection process, and a solution that fits your business perfectly. Let us power your success with reliable power transmission gearboxes designed for your specific needs.