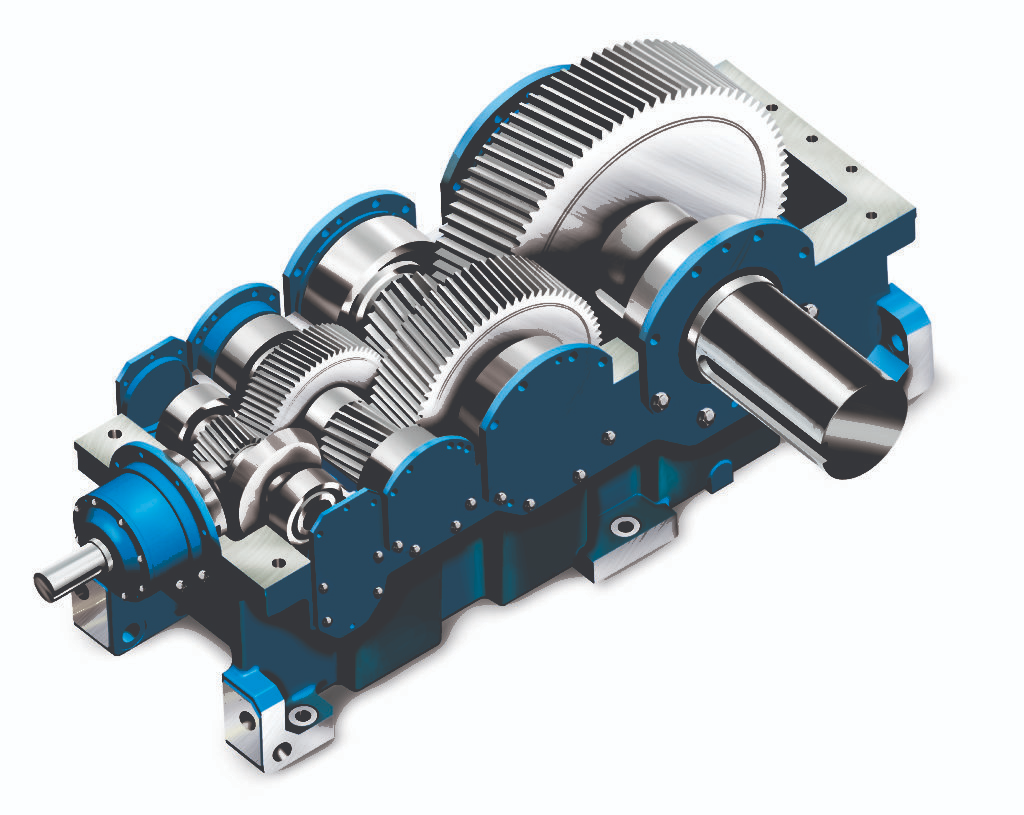

Industrial gearboxes are used to modify the ratio of speed sent to the transmitted power. For light-duty industrial automation applications, industrial gearboxes, mechanical speed variator, and gear motors smoothen the flow of operations.

Whatever gearbox you pick look for quality and durability. The quality doesn’t only mean fine raw material or robust internal small parts used, but it also means perfection in cuts and designs. It should be according to your specification of the work if you want gearboxes to play a major role in your work.

It should go through various efficiency tests and failure analyses. Problems in the small components of the industrial gearbox may reduce the efficiency. Buy them from only trusted brands or engineers for the best outcomes.

Of course, buying Industrial Gearboxes is a capital investment, so you would look for more and more features at the same prices. According to industry type and use, choose the size, design, and style of gearboxes.

Industry size and purpose play a vital role in the selection of any industrial gearbox. Consider the frequent check-ups and quality servicing facility from where you purchase the industrial gearboxes. It will help in the longevity and performance of the gearboxes.

The Benefits of Using The Finest Quality Gearboxes are:

-

No complexity and convenient to operate.

-

Upgrade the original performance.

-

Increase productivity and efficiency.

-

Save time and cost.

-

Lesser maintenance cost.

-

Reduces the noise.

-

Increment in operational output in a shorter period of time.

-

Less consumption of power.

Except for these, designer and quality gearboxes have less wear and tear and they have good duration compared to cheap products. Though it may cost high, you will get the worth of every extra buck in the long run.

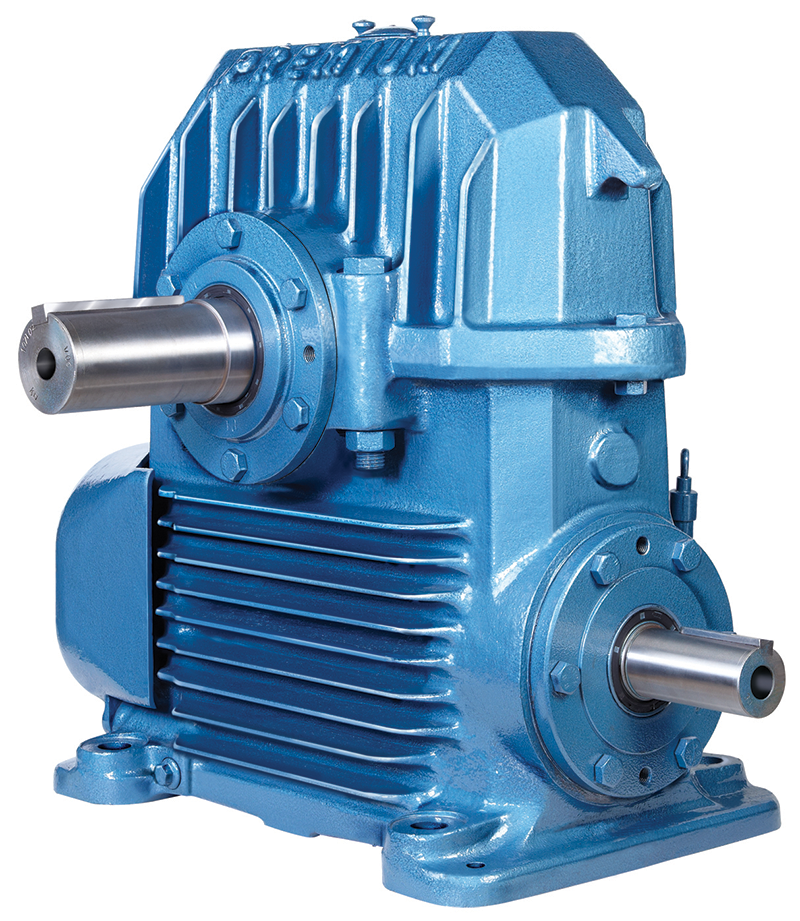

There are different kinds of gearboxes used in different industries serving vivid purposes. In this reference, Worm Gearbox boosts efficiency levels. You can choose a single or double reduction worm gearbox according to the purpose and need. The best thing about the worm gearbox is that it achieves higher torque in the low-speed gear ratio.

The design is simple and compact with robust construction. There is no need of spending additional maintenance costs with these warm gearboxes. Unlike industrial gearboxes, you can use worm gearboxes for automobiles, industrial equipment, mining, and the oil or petroleum extraction industry. It is also used for tuning instruments.

Apart from handling speed, there is a special feature in them, which is called a self-locking system. Worm gears are complex compared to industrial gears.

Furthermore, there are many styles and designs of gearboxes, and each style has a specific use. Inline, tee, right angle, and crossed axis gearboxes are some of the most common examples of gearbox styles.

These gearboxes contain robust teeth that not only control noise and pollution but also provide higher output in lesser time. Take the help of technical experts in case of any complexity. Read the guidelines of every new product or let it be handled by experts or hired engineers.