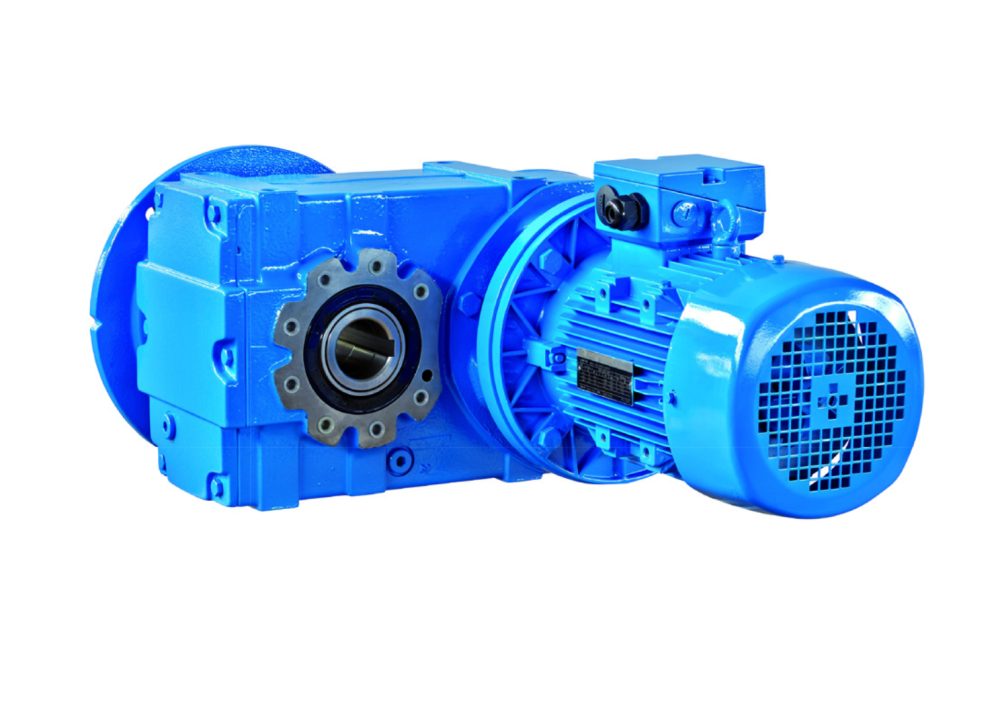

When it comes to gearboxes, they are generally distinguished into two categories: Worm Gearbox and Helical Gearbox. Amongst the two, the helical gearbox has always been popular in the industry and mechanical operations.

Although in recent years, with technological advancements and development, worm gearbox manufacturers have managed to bridge the gap between the two gearboxes. According to worm gearbox manufacturers, these gearboxes now provide offer specific benefits and efficiencies that helical gearboxes cannot.

What Is A Worm Gearbox?

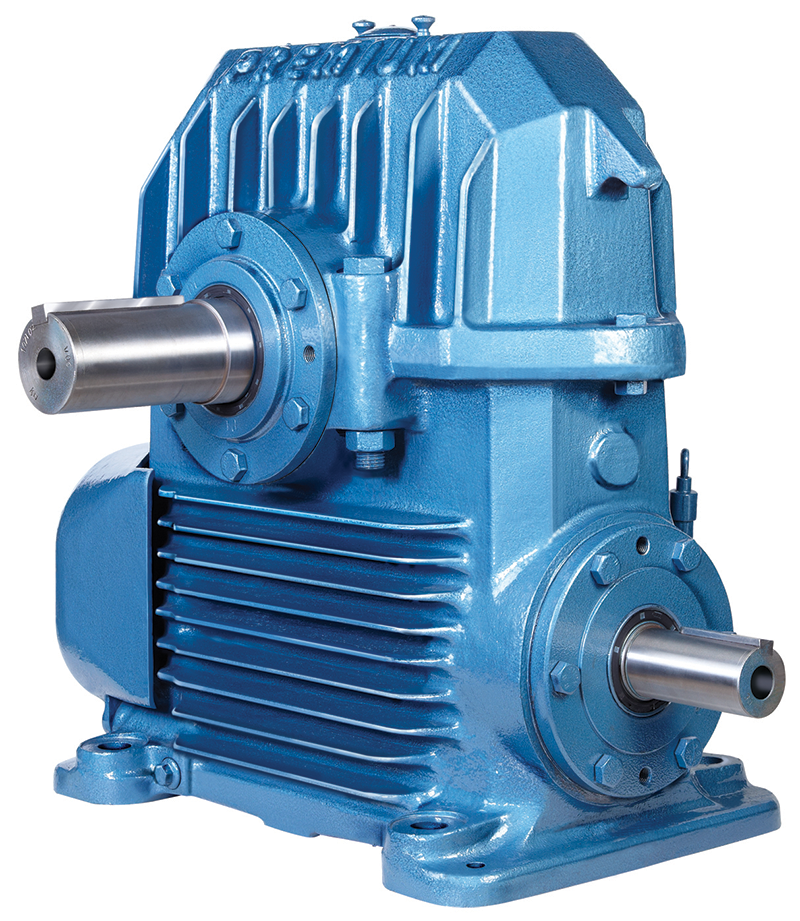

A worm gearbox utilises an assortment of shafts, bearings, toothed wheels and worm gears to create motion. Worm gearboxes are required in numerous mechanical procedures and engines. They can also modify the input rotational movement by 90 degrees to the output.

Inside a Worm Gearbox

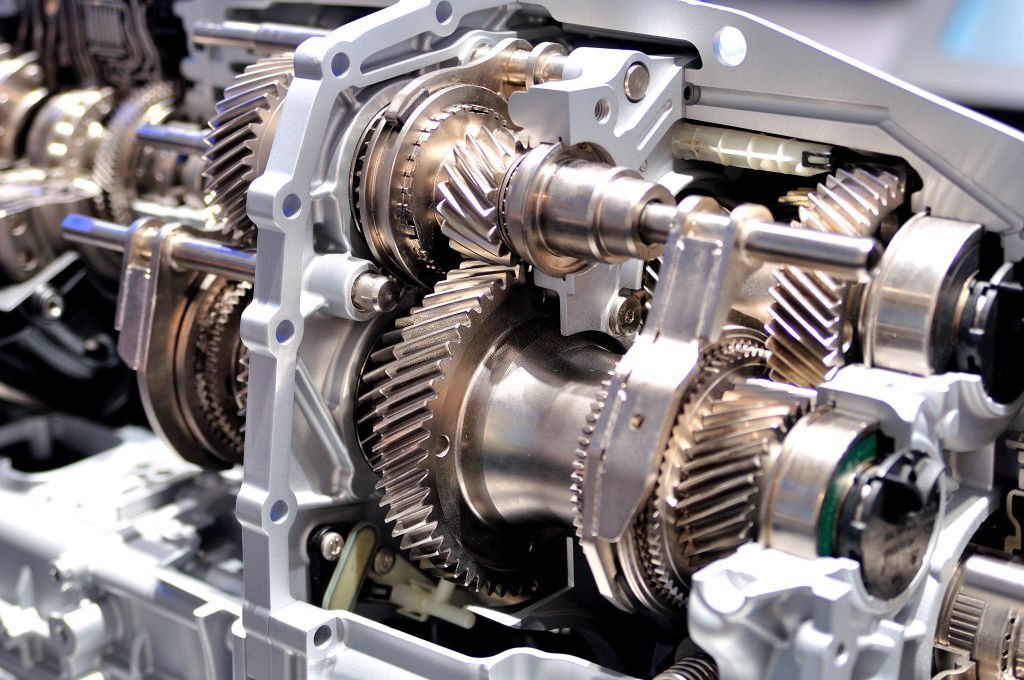

When a worm gear spins, it allows the toothed wheel placed inside to move. The previous design of the worm gearbox used to be erratic, unreliable, and inadequate to function, but the interior redesign and upgraded components improved its functionality. Due to this improvement, worm gearbox manufacturers can now produce worm gearboxes that can change rotational direction, amongst other things. However, worm gearboxes require higher levels of lubrication due to their heightened friction rate.

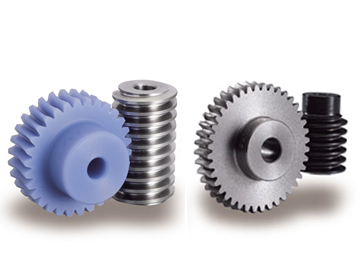

What Is A Worm Gear?

According to worm gearbox manufacturers, worm gears are crucial to worm gearboxes and their operations. Worm gears are a form of mechanical gear employed in a few drive systems and most gearboxes. The shaft in this has several lengths on the basis of application, as well as a geared spiral section. The teeth on the gears spiral are a necessary part of the design to work with the toothed wheel. When the worm gear is in the proper position, it will move the toothed when rotation takes place.

The teeth on a worm gear must be at an angle to ensure they can slot into the toothed wheel. The fit should ideally be tight to decrease any backlash or unnecessary motion in the gearbox.

Where Are Worm Gearboxes Employed?

Worm gearboxes are employed throughout the entire industry for numerous applications. They are commonly utilised on applications requiring high speed. Here are some of the most common usages of worm gearboxes:

- Conveyor belts

- Presses

- Manufacturing machinery

- Rolling mills

- Lifts

- Mining applications

- Hoists

- Packing machinery

- Escalators

Advantages Of Worm Gearboxes

The number of worm gearbox manufacturers has increased throughout the years due to the heightened demand for worm gearboxes. Let us look at all the advantages of the worm gearbox that make it so popular.

Compact

Worm gearboxes are designed to be one of the most compact gearboxes in the market. It achieves this level of compactness as the worm gear can change drive direction by 90 degrees.

Worm gearboxes are perfect for applications requiring high torque but limited speed.

Increase Torque

This gearbox increases the torque to a significant extent in the mechanical system. Due to the unique worm gear design, they mesh with the worm wheel and produce high torque outputs.

Quiet Operation

Worm gearbox manufacturers create worm gearboxes to be one of the quietest gearboxes in the industry. This is perfect for applications where noise levels need to be maintained strictly. Although you need to ensure they are not worn out, incorrectly mounted, or not well-lubricated, as that can make this gearbox noisy.

Decrease the System Speed

Worm gearboxes can also be employed to decrease the mechanical system’s speed. They obtain this by containing a series of high-ratio gears. It is an excellent benefit if you intend to adjust the output speed without modifying the motor or engine arrangement. A worm gearbox is easy to bolt on the end of the drive to make this feasible.

Disadvantages Of Worm Gearboxes

Much like any mechanical equipment, worm gearboxes also have certain disadvantages. Here are some of the disadvantages of operating a worm gearbox:

Require Regular Maintenance

Worm gearboxes work smoothly, without any hiccups, and have good operational longevity only if they receive frequent maintenance. These gearboxes require regular inspection of the toothed wheel, worm gear and more to ensure that there are no signs of damage or wear.

Frequent Lubrication

To ensure that worm gearboxes remain completely operational, they need regular lubrication. Worm gearbox manufacturer ensures that specialised lubricant is used on a regular basis. This process helps with the amount of friction between the toothed wheels and the worm gears.

Where To Find The Best Worm Gearbox Manufacturers In India?

Are you searching for the best premium Gearbox or worm gearbox manufacturer in India? Then look no further than Santram Engineers. We are India’s most trusted worm gearbox manufacturer with decades of expertise in the field.

For assistance regarding worm gearboxes, you can call us at +91-96247 39393 or write to us at sales@santramengineers.com. We would be happy to assist you.