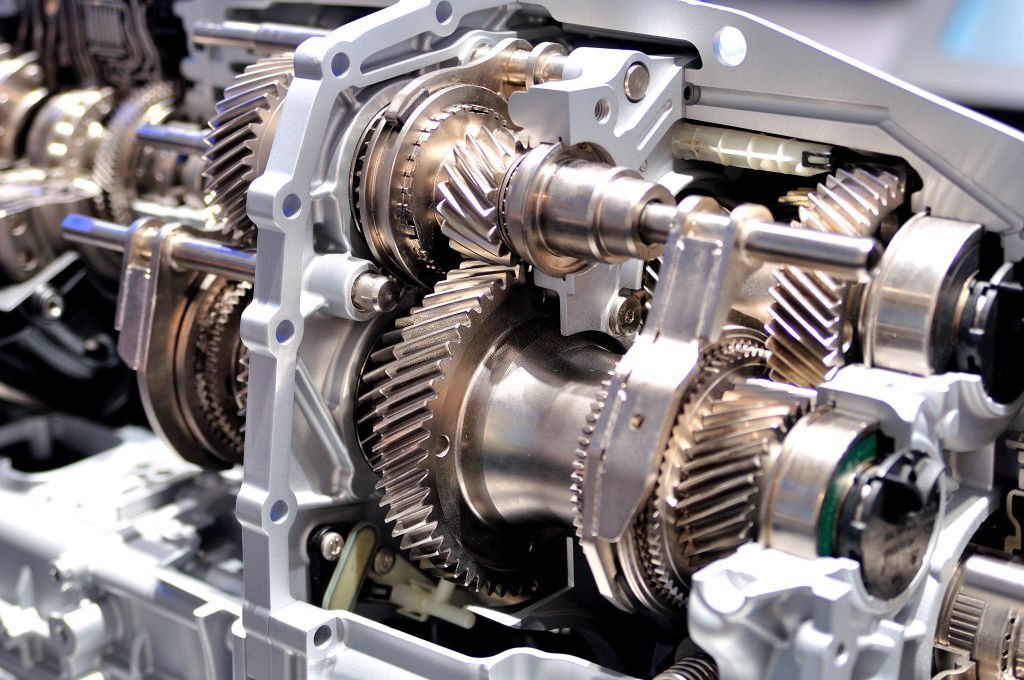

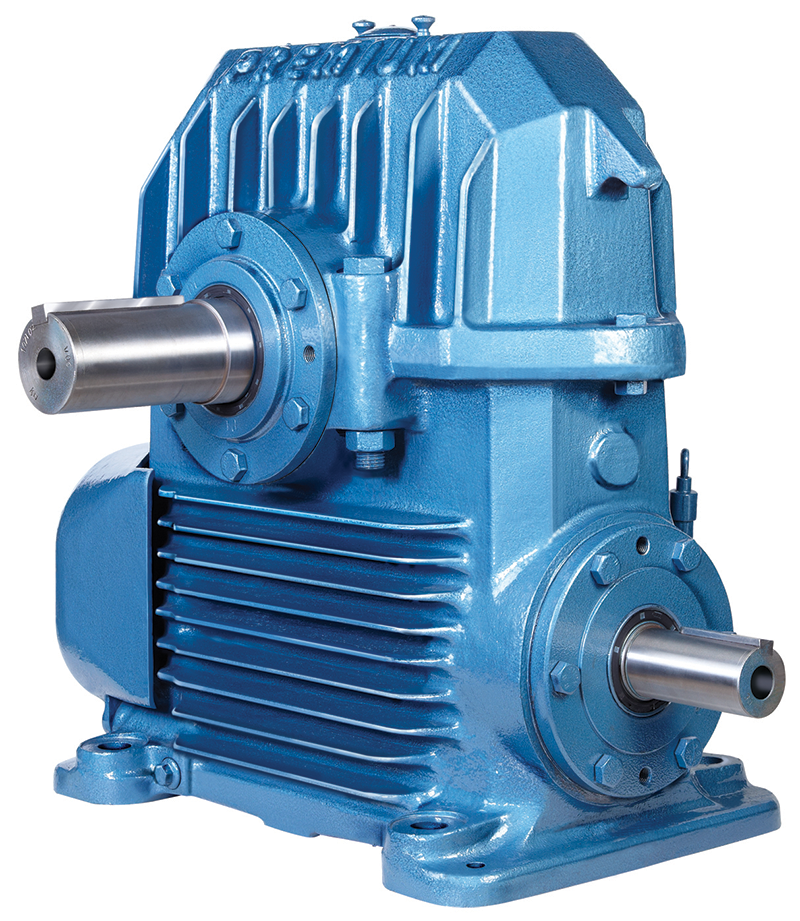

Worm gearboxes play a critical role in various industries that require precise control of speed and torque. They are especially valued for their compact design and ability to transmit power at right angles. Among worm gearboxes, single-start and two-start configurations are popular. Understanding their differences is essential for businesses to make informed decisions when choosing the right gearbox for specific applications.

What is a Single-Start Worm Gearbox?

Definition and Construction

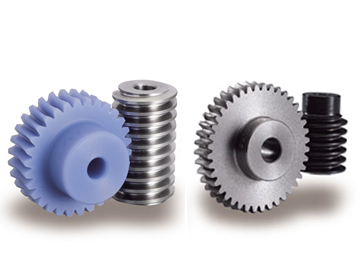

A single-start worm gearbox consists of a worm and a worm wheel, where the worm has a single continuous thread running around its circumference. This simple construction allows the worm to engage the teeth of the worm wheel, typically resulting in a high reduction ratio. The worm in this configuration rotates once for each complete turn, advancing the worm wheel by just one tooth.

Performance Characteristics

Single-start worm gearboxes offer excellent performance in applications requiring high torque and low-speed ratios. The gear reduction is significant, as the gearbox can reduce speed significantly with a single turn of the worm shaft. This makes it ideal for operations requiring slow, controlled movements.

Advantages

High Torque Output:

Single-start worm gearboxes are renowned for their ability to produce high torque. This feature is particularly valuable in applications where significant force is required. For instance, in machinery like industrial presses or heavy-duty conveyor systems, high torque ensures heavy loads are moved efficiently and reliably. The single-thread design of the worm allows for a substantial gear reduction, making it ideal for applications that need gradual and controlled movement, such as in lifts and winches.

Compact Design:

The simplicity of the single-start worm gearbox design contributes to its compactness. This compactness is advantageous in equipment design, where space constraints are a concern. The gearbox’s ability to provide a high reduction ratio within a relatively small footprint makes it suitable for integration into tight spaces. This design efficiency saves valuable space and reduces the overall weight of the machinery, potentially lowering shipping and installation costs.

Self-Locking Capability:

One of the notable advantages of single-start worm gearboxes is their self-locking feature. This characteristic prevents the gearbox from being driven backwards by external forces. Self-locking is particularly beneficial in applications where load stability is crucial, such as in lifting and hoisting systems. It ensures that once the gearbox is stopped, it will not reverse or drop the load, enhancing safety and control in various industrial operations.

Disadvantages

Lower Efficiency:

Despite their advantages, single-start worm gearboxes are less efficient compared to other gearbox types. The primary reason for this inefficiency is the high friction generated between the worm and the worm wheel. This friction leads to significant energy losses, which are manifested as heat. In continuous or high-load applications, this reduced efficiency can lead to increased energy costs and the need for more frequent cooling or lubrication interventions to manage heat buildup.

Slower Speed:

The gear reduction capability of a single-start worm gearbox results in slower output speeds. While this slow speed is beneficial for applications requiring precise control, it can be a limitation in processes that need higher operational speeds. For instance, in applications like high-speed conveyor systems or machinery where faster movement is required, the single-start worm gearbox might not be suitable. The slower speed can impact overall productivity and operational efficiency in such cases.

Higher Wear and Tear:

Single-start worm gearboxes are prone to higher wear and tear due to the increased contact area between the worm and the worm wheel. The constant friction and load transfer can lead to quicker degradation of the gearbox components. This wear and tear necessitates more frequent maintenance and replacement of parts, which can lead to higher operational costs over time. Regular inspections and timely maintenance are essential to ensure the longevity and optimal performance of the gearbox. However, these requirements add to the overall maintenance burden.

What is a Two-Start Worm Gearbox?

A two-start worm gearbox differs from the single-start variety by having two threads running around the worm’s circumference. This results in the worm advancing the worm wheel by two teeth for each complete turn of the worm shaft. While the basic structure remains similar to a single-start gearbox, the dual-thread design changes the performance dynamics.

Performance Characteristics

Two-start worm gearboxes provide a balanced approach between speed and torque. With two threads, they achieve faster output speeds than single-start gearboxes while maintaining a substantial reduction ratio. However, this increase in speed comes with a slight reduction in torque compared to single-start systems.

Advantages

Improved Efficiency:

Two-start worm gearboxes have distinct advantages in efficiency due to their design. The dual-threaded worm reduces friction between the worm and the worm wheel compared to a single-start gearbox. This reduction in friction results in less heat generation, which means that the gearbox operates more smoothly and conserves more energy. In practical terms, this improved efficiency can lead to lower energy consumption and reduced operating costs. For industries where energy efficiency is a priority, such as in high-volume manufacturing or processing plants, the efficiency gains from using this gearbox can be substantial.

Faster Speed:

One of the key benefits of a two-start worm gearbox is its ability to provide higher output speeds. The dual threads allow the worm to engage the worm wheel more effectively, leading to faster rotation of the output shaft. This characteristic is particularly valuable in applications where speed is essential, such as in conveyor systems, automated assembly lines, or machinery requiring quick adjustments. The increased speed capability ensures operations can proceed at a faster pace, enhancing productivity and throughput in various industrial settings.

Moderate Torque Output:

While two-start worm gearboxes do not achieve the same high torque levels as single-start gearboxes, they still offer a respectable amount of torque for many applications. The dual-start design provides a balanced approach, delivering adequate torque for a range of industrial uses without compromising significantly on speed. This makes two-start gearboxes suitable for applications that require a combination of moderate torque and higher speed, such as in packaging machinery, food processing equipment, or material handling systems.

Disadvantages

Lower Reduction Ratio:

A notable disadvantage of two-start worm gearboxes is their lower reduction ratio compared to single-start ones. The dual-thread design means that while the gearbox can achieve higher speeds, it does so with a reduced capacity for speed reduction. This can be a limitation in applications where extremely low speeds are required, such as in precise positioning systems or slow-moving machinery. The lower reduction ratio might necessitate the use of additional gear stages or alternative solutions to achieve the desired slow speed, potentially complicating the design and increasing costs.

Lesser Self-Locking Ability:

The self-locking feature of worm gearboxes, which prevents the gearbox from being driven backwards by external forces, is less pronounced in two-start designs. The two-start configuration means that the self-locking effect is not as strong as in single-start gearboxes. This can be a drawback in applications where preventing back-drive is critical, such as in lifting systems, vertical conveyors, or other equipment where load stability and safety are paramount. Without a robust self-locking mechanism, additional measures may be needed to ensure load security and prevent unwanted movement.

Key Differences Between Single-Start and Two-Start Worm Gearboxes

Gear Ratio and Speed

The gear ratio is one of the most significant distinctions between single-start and two-start worm gearboxes. A single-start worm gearbox provides a higher reduction ratio, meaning it can achieve a significant reduction in speed with each turn of the worm. This makes it ideal for applications that require slow, precise movements.

In contrast, a two-start worm gearbox, with its dual-thread design, results in a lower gear ratio. Although it still provides considerable reduction, it allows for faster output speeds compared to the single-start variant. This is advantageous for applications where higher speed is necessary while maintaining control over torque.

Torque and Power Efficiency

Single-start worm gearboxes excel in delivering high torque output. The increased number of gear teeth engaged at any given time means that they can handle higher loads. However, this comes at the cost of reduced power efficiency. The high friction between the worm and worm wheel in a single-start gearbox leads to greater energy loss, which manifests as heat. This can impact the overall efficiency of the system, especially in continuous operation scenarios.

On the other hand, two-start worm gearboxes offer improved power efficiency due to reduced friction. The dual-thread design spreads the load more evenly, leading to lower energy loss and less heat generation. Although they provide slightly less torque than single-start gearboxes, their efficiency makes them a preferable choice in many applications where power consumption and heat management are critical.

Wear and Durability

The wear and durability of worm gearboxes are influenced by the contact surface between the worm and the worm wheel. Single-start worm gearboxes, due to their design, often experience higher wear and tear. The greater friction generated can lead to faster degradation of the gear components, requiring more frequent maintenance and replacement.

Two-start worm gearboxes generally exhibit better durability. The reduced friction and more efficient load distribution contribute to less wear over time. As a result, they often have a longer service life and lower maintenance requirements compared to their single-start counterparts. This can translate to cost savings and improved reliability in industrial operations.

Cost and Complexity

Single-start gearboxes are typically less complex in terms of design and manufacturing, which often makes them more cost-effective. Their straightforward construction results in lower production costs, and they are generally easier to maintain and repair.

Two-start worm gearboxes, while offering improved performance characteristics, can be more expensive due to their more complex design. The added intricacy in the construction also means they may require more specialized maintenance. However, the higher initial investment can be justified by their improved efficiency and durability, making them a valuable option in applications where these factors are critical.

Applications of Single-Start Worm Gearboxes

Use in Low-Speed, High-Torque Applications

Single-start worm gearboxes are particularly well-suited for low-speed, high-torque applications. Their ability to provide a high reduction ratio makes them ideal for machinery and equipment that require slow and controlled movement. Examples include lifting and hoisting systems, conveyor systems, and various industrial machines where precise speed control and substantial torque are necessary.

Advantages in Specific Industrial Settings

In industries where precise control and high torque are crucial, such as in manufacturing and material handling, single-start worm gearboxes offer significant advantages. Their self-locking ability prevents back-driving, making them suitable for vertical applications where load holding is essential. The compact design of single-start gearboxes also helps in space-constrained environments, providing a reliable solution without compromising on performance.

Find the Perfect Industrial Gearbox Solution for Your Project

Santram Engineers is one of the leading industrial gearbox suppliers in India, with a strong presence in major cities like Mumbai, Hyderabad, and Bangalore, as well as other locations nationwide.

Discover how our range of worm gearboxes and other industrial gearboxes can meet your specific needs with precision and efficiency. Whether you’re looking for high torque, compact design, or improved speed, our expert team is here to guide you through the selection process.

Call us at +91-96247 39393 or email us at sales@santramengineers.com for a personalized consultation and find the perfect gearbox solution tailored to your unique challenges. Maximize your project’s performance and reliability. Reach out now and let’s get started!