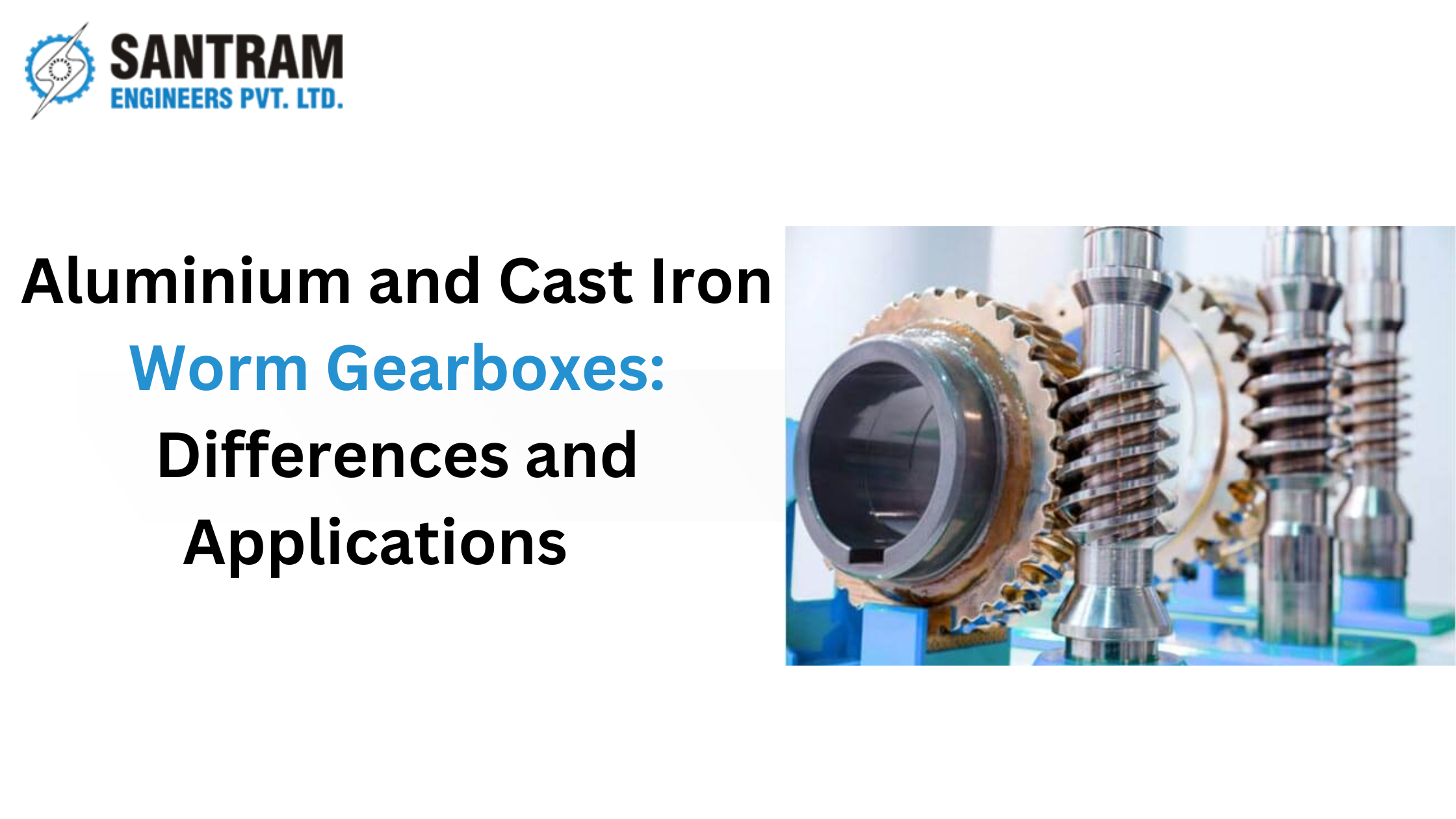

Worm gearboxes are essential components in various industries, offering efficient power transmission and speed reduction. Among the most commonly used gearboxes are those made from aluminium and cast iron. Both materials offer distinct advantages and limitations, depending on the application needs. Understanding the differences between aluminium and cast iron worm gearboxes can help businesses select the right gearbox for their operations.

This article explores the characteristics, features, and applications of aluminium worm gearboxes, followed by a comparison with cast iron counterparts.

Aluminium Worm Gearboxes

These are known for their lightweight construction and corrosion-resistant properties, making them popular in industries where weight reduction and environmental resistance are critical. These gearboxes are typically used in applications requiring moderate loads and speeds, offering versatility across a wide range of operations.

Characteristics and Features

Aluminium worm gearboxes have several characteristics that make them stand out in industrial applications:

- Lightweight and Corrosion-Resistant Properties: One of the most significant advantages of aluminium gearboxes is their lightweight construction. This feature makes them ideal for applications where weight reduction is crucial, such as in mobile machinery. Additionally, aluminium is inherently resistant to corrosion, making these gearboxes suitable for use in harsh environments or industries exposed to moisture, chemicals, or salt.

- High Thermal Conductivity: Aluminium has excellent thermal conductivity, allowing for better heat dissipation compared to other materials. This feature ensures the gearbox operates efficiently, even in high-temperature environments. It also reduces the risk of overheating, which can extend the service life of the gearbox and lower the need for frequent repairs.

- Cost-Effectiveness: In terms of material and manufacturing, aluminium worm gearboxes are more cost-effective compared to their cast iron counterparts. Aluminium is easier to manufacture, reducing production costs while maintaining performance quality. This affordability makes these gearboxes an attractive option for businesses looking to minimise expenses without sacrificing operational efficiency.

Advantages of Aluminium Worm Gearboxes

- Lightweight and Moderate-Load Applications: These gearboxes are perfect for industries that require lightweight components without compromising on performance. Their ability to handle moderate loads makes them ideal for conveyors, packaging machines, and light-duty transport systems.

- Weight Reduction in Mobile Machinery: In industries where machinery is frequently moved or transported, such as construction or mining, aluminium worm gearboxes provide the added benefit of weight reduction. This feature can improve the overall mobility of the machinery and reduce fuel or energy consumption.

- Lower Maintenance Requirements: Thanks to aluminium’s natural resistance to rust and corrosion, these gearboxes require less maintenance compared to other materials like steel or cast iron. This translates to lower long-term costs for businesses, as there is less need for regular servicing or component replacement.

Limitations of Aluminium Gearboxes

- Lower Strength and Wear Resistance: Aluminium worm gearboxes are not as strong or durable as those made from cast iron. They are more prone to wear and tear, making them unsuitable for applications that involve heavy-duty loads or high-impact operations.

- Not Suitable for Heavy-Duty Applications: They may not be the best choice for industries requiring robust performance under extreme conditions. In such cases, cast iron gearboxes provide better strength and durability.

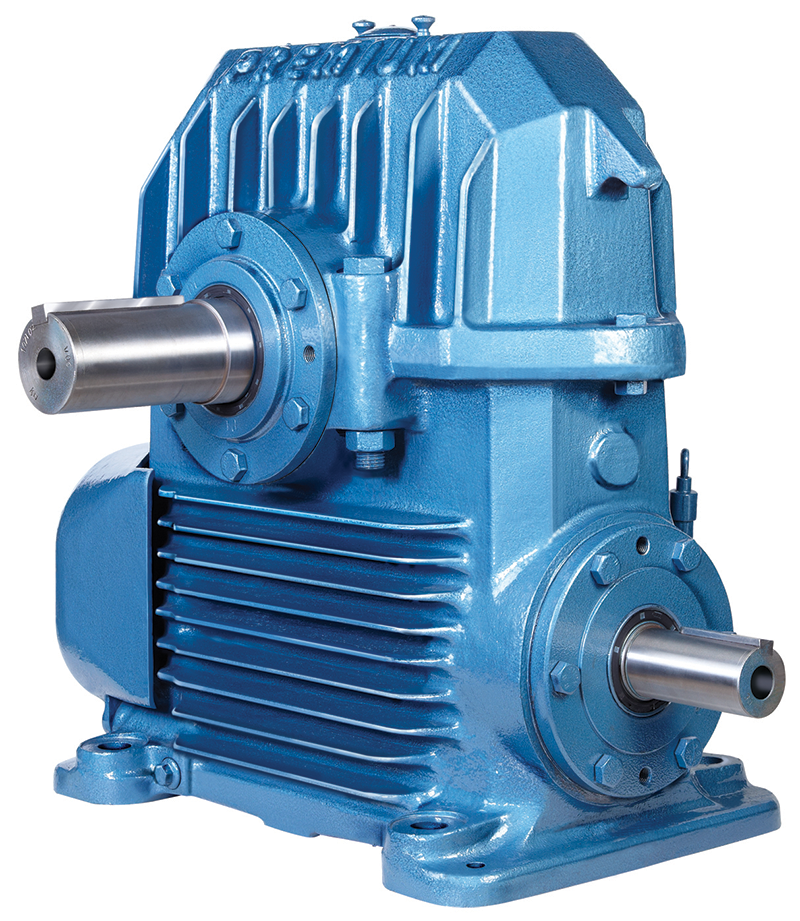

Cast Iron Worm Gearboxes

These are renowned for their strength and durability, making them a preferred choice for heavy-duty applications in various industries. Their robust construction allows them to perform efficiently under high loads and challenging operating conditions.

Characteristics and Features

Cast iron worm gearboxes possess several key characteristics that set them apart from their aluminium counterparts:

- High Tensile Strength and Durability: Cast iron is known for its exceptional tensile strength, which enables these gearboxes to withstand significant stress and strain. This characteristic makes them particularly suitable for industries that require reliable performance in demanding conditions.

- Better Vibration Damping and Shock Absorption: Cast iron’s natural density allows it to absorb vibrations more effectively than lighter materials. This feature minimises the transmission of vibrations throughout the machinery, reducing wear on components and enhancing overall performance.

- Greater Wear Resistance: Cast iron worm gearboxes exhibit superior wear resistance, making them ideal for heavy-duty industrial applications. They can endure prolonged usage without significant degradation, ensuring consistent performance over time.

Advantages of Cast Iron Worm Gearboxes

- Ideal for High-Load Applications: Cast iron worm gearboxes excel in environments where heavy loads are common. Industries such as mining, construction, and manufacturing often rely on these gearboxes for their ability to handle substantial weight without compromising efficiency.

- Long Lifespan and Better Performance Under Stress: The durability of cast iron translates to a longer operational lifespan for worm gearboxes. This longevity reduces the need for frequent replacements, saving businesses money on maintenance and downtime. Additionally, these gearboxes perform well under stress, maintaining stability even when subjected to extreme conditions.

- Higher Torque and Power Transmission: Cast iron gearboxes can efficiently transmit higher torque, making them suitable for applications that demand significant power. This capability is crucial in scenarios where machinery needs to operate at peak performance levels.

Limitations of Cast Iron Gearboxes

- Heavier than Aluminium Gearboxes: One of the primary drawbacks of cast iron gearboxes is their weight. While this weight contributes to their strength, it can be a disadvantage in applications where weight reduction is critical. This factor can affect the mobility and fuel efficiency of equipment.

- Susceptibility to Rust in Corrosive Environments: Although cast iron is durable, it is more susceptible to rust and corrosion than aluminium, especially in moist or chemically aggressive environments. Proper maintenance and protective coatings are essential to prolong the lifespan of cast iron gearboxes in such conditions.

- Typically Higher Costs: The initial investment for cast iron worm gearboxes is generally higher than that for aluminium models. This cost is attributed to the material’s strength and the manufacturing processes involved. Businesses must weigh the long-term benefits against the upfront costs when considering their options.

Applications of Aluminium Worm Gearboxes

Aluminium worm gearboxes are widely used across various industries due to their lightweight design, ease of maintenance, and excellent corrosion resistance. These features make them particularly suitable for applications where performance and efficiency are critical. Below are some key industries and uses for these worm gearboxes.

Industries and Uses

- Automotive and Conveyor Systems: In the automotive industry, these gearboxes are utilised for their lightweight properties, making them easy to integrate into various machinery. Their low weight reduces overall equipment mass, which can lead to increased fuel efficiency in vehicles and reduced energy consumption in conveyor systems. This is especially advantageous in applications where speed and mobility are essential.

- Packaging Machinery: Aluminium gearboxes are ideal for packaging machinery, which often requires moderate load capacity and high-speed operations. Their ability to handle dynamic loads with minimal maintenance makes them a preferred choice for packaging lines where consistent performance is crucial.

- Food Processing Equipment: The food processing industry demands strict hygiene standards. Aluminium’s natural resistance to corrosion makes it suitable for use in environments where cleaning is frequent and necessary. These gearboxes can withstand exposure to various cleaning agents, ensuring longevity while meeting hygiene requirements.

- Agricultural Equipment: In agriculture, where machinery often needs to be mobile and lightweight, aluminium worm gearboxes play a vital role. Their reduced weight helps improve the efficiency of tractors and harvesters, making them easier to manoeuvre in the field. Additionally, the low maintenance requirements allow farmers to focus on productivity rather than equipment upkeep.

Why Aluminium Gearboxes are Chosen in These Applications

The choice of aluminium worm gearboxes in these applications is largely due to their lightweight nature, low maintenance needs, and corrosion resistance. In sectors like food processing and agriculture, where cleanliness and efficiency are paramount, these gearboxes offer a perfect balance of performance and reliability. Their lightweight design contributes to enhanced mobility and reduced energy consumption, making them suitable for modern machinery that prioritises efficiency.

Applications of Cast Iron Worm Gearboxes

Cast iron worm gearboxes are well-known for their robustness and ability to withstand extreme conditions. This durability makes them a top choice for industries that demand high performance under significant stress. Below are some prominent industries and their applications for cast iron gearboxes.

Industries and Uses

- Mining and Heavy Machinery: In the mining sector, equipment must endure heavy loads and harsh environmental conditions. Cast iron gearboxes are specifically designed to handle these challenges, providing reliable performance in excavators, loaders, and other heavy machinery. Their strength ensures they can withstand the impact of heavy materials, making them essential for mining operations.

- Steel and Cement Manufacturing: The steel and cement industries require gearboxes that can handle high-torque processes. Cast iron worm gearboxes provide the necessary strength to endure the demanding environments of these industries. They are integral to various manufacturing processes, including mixers and conveyors, where consistent performance and durability are crucial.

- Oil and Gas Industry: The oil and gas sector operates in some of the most extreme environments, requiring equipment that can perform reliably under stress. Cast iron gearboxes are known for their rugged durability, making them suitable for drilling rigs and offshore platforms. They can handle the extreme pressure and temperatures associated with these applications, ensuring safety and operational efficiency.

- Material Handling: In material handling applications, high shock resistance is vital. Cast iron worm gearboxes excel in lifting and handling systems, where sudden loads and impacts are common. Their ability to absorb shock reduces wear on other components, extending the lifespan of the entire system.

Why Cast Iron Gearboxes are Preferred for Heavy-Duty Applications

Cast iron worm gearboxes are preferred in heavy-duty applications due to their unparalleled durability, strength, and longevity. In industries where equipment must operate under high stress and demanding conditions, these gearboxes provide the reliability necessary to maintain productivity. Their ability to handle high torque and absorb shock makes them indispensable for businesses that cannot afford downtime or equipment failure.

Key Differences Between Aluminium and Cast Iron Worm Gearboxes.

When selecting the appropriate worm gearbox for your application, understanding the key differences between aluminium and cast iron options is essential. Below is a comparison of their primary characteristics:

| Feature | Aluminium Worm Gearboxes | Cast Iron Worm Gearboxes |

| Material Strength | Moderate strength, suitable for lighter loads | High tensile strength, ideal for heavy-duty applications |

| Durability | Less durable under extreme conditions | Excellent durability; withstands harsh environments |

| Weight | Lightweight, enhancing mobility | Heavier, which can impact equipment portability |

| Ease of Installation | Easier to handle due to low weight | More cumbersome to install because of the weight |

| Cost | Generally lower initial costs | Higher due to material and manufacturing processes |

| Manufacturing | Cost-effective and easier to fabricate | Requires more complex processes due to strength |

| Corrosion Resistance | Excellent, ideal for wet environments | Susceptible to rust unless properly coated |

| Thermal Conductivity | High thermal conductivity aids heat dissipation | Lower thermal conductivity compared to aluminium |

By consulting with reliable gearbox manufacturers and utilising professional industrial gearbox services, businesses can enhance their operational efficiency and longevity.

Factors to Consider When Choosing Between Aluminium and Cast Iron Worm Gearboxes

Here are essential factors to consider when choosing between aluminium and cast iron worm gearboxes:

- Load Capacity and Torque Requirements: Determine the load capacity and torque specifications of your application. Aluminium gearboxes are suitable for lighter loads, while cast iron gearboxes can handle high-torque and heavy-duty applications effectively.

- Environmental Conditions: Consider the operating environment. If the gearbox is exposed to moisture or corrosive substances, aluminium’s corrosion resistance makes it a better option. In contrast, cast iron is more suited for rugged environments where durability is critical.

- Weight and Space Constraints: Assess the weight and space limitations of your machinery. Aluminium gearboxes are lighter and easier to install in compact spaces, while cast iron gearboxes are bulkier but provide greater strength.

- Cost vs. Longevity: Evaluate your budget and the long-term costs associated with each option. While aluminium gearboxes are often less expensive initially, cast iron gearboxes may offer better longevity and lower maintenance costs.

- Maintenance and Lifespan: Consider maintenance needs. Aluminium gearboxes require less upkeep, while cast iron gearboxes, though durable, may need protective coatings to prevent rust.

Get Expert Advice on Choosing the Right Worm Gearbox for Your Industry

Navigating the world of worm gearboxes can be challenging, but you don’t have to do it alone! At Santram Engineers, our team of industry experts is here to provide you with the guidance you need to make informed decisions.

Choosing the right worm gearbox is critical for optimising performance, enhancing efficiency, and prolonging the lifespan of your equipment. Whether you’re in automotive, food processing, or heavy machinery, we understand the unique demands of your industry.

Let our knowledgeable professionals help you assess your specific requirements, including load capacity, environmental conditions, and maintenance needs.

Contact us at +91 96247 39393 or email us at sales@santramengineers.com for a personalised consultation. Discover how our expertise can lead you to the perfect worm gearbox solution tailored to your operational needs. Your success starts with the right choices—let’s make them together!