Small and large-scale industries all around the world consider helical gearboxes indispensable to enhance production. But before we understand their importance, it is imperative

to ask what is a helical gearbox.

What is A Helical Gearbox?

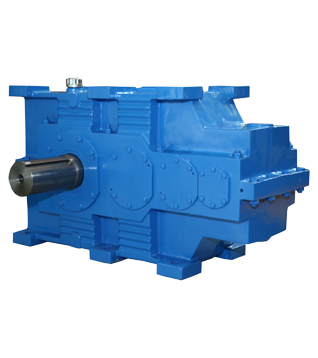

Among all gearboxes, the helical gearbox is considered one of the most effective in any industrial usage, which is usually facilitated with the help of their configuration.

They are essentially power transmission instruments employed to improve the torque and decrease the speed amidst turning shafts. They are usually separated into two categories; one is responsible for transmitting energy between the parallel parts. The other one is dedicated to transferring power amongst the non-parallel components.

A helical gearbox operates quieter and has a smoother performance compared to other gearboxes due to its helical gears. The helical gears comprise unique teeth positioned at a specific angle to the shaft. Due to this positioning, more than one tooth is in contact during the operation, allowing the gear to withstand higher load levels.

The production and the modular structure also enable manufacturers to incorporate numerous benefits in terms of engineering and execution. Some of them being interchangeable elements, subassemblies and more. This ensures more economical construction while attaining the highest component quality and integrity.

Different Types Of Helical Gearbox

Depending on the various needs and necessities of different industries, several modifications are made to helical gearboxes.

1. Single Helical Gear

One of the most straightforward modifications to a helical gearbox is the single helical gear. They are the ones that are placed at a distinct angle to the axis. This allows the dual-hand

orientation of the gears. The main reason why single helical gear is preferred is due to the availability of additional surface area in contact and its power capacity.

2. Double Helical Gear

The double helical gear is a sub-division of your average helical gearbox. In this case, two helical sections are placed side by side with only the gap separating them. Their determining factor is

every section has helix angles that are alike yet opposite. The benefit of employing double helical gears is that it eliminates thrust forces and allows efficient performance and increased tooth overlap.

3. Herringbone Gear

The herringbone gear and the double helical gear are quite similar, but the herringbone gear is differentiated by the lack of space that divides the two helical faces. The herringbone

type of helical gearbox tends to be smaller in size and is ideal for shock cases and intense vibration. Although you will rarely see herringbone gear as they are not usually employed because of their price range and complicated production process. Similar to the previous gears, the herringbone

gear eliminates thrust in a more gear-oriented method. The method employed is that one-half of the face is clipped from one direction while the other half is done from the

other direction. The entire process balances the thrust enhanced by the gear.

Why Should Industries Opt For Helical Gearbox?

A helical gearbox operates with the support of cylindrical gears. The teeth in these gears are not parallel to each other on the turning axis; instead,

the aforementioned teeth are a part of a helix. This formation allowed the power to be transformed between either right or parallel angle axes.

Now you may wonder what the difference is between a and numerous other gearboxes. Essentially the helix created by the teeth gives the gearbox the ability

to function quietly. The helical gearbox has the edge over all other gearboxes because it can transmit power more efficiently amidst two parallel shafts.

There is also a significant reduction in the average wear and tear as the multiple teeth distribute power much more evenly.

Industries That Prefer The Helical Gearbox

Almost all notable producers of superior quality, industrial-grade gearboxes recommend the helical gearbox to their clients and consumers.

They are ideal for operation under heavy power efficiency and silent operation (automotive systems).

Some of the Industries that actively prefer this Gearbox:

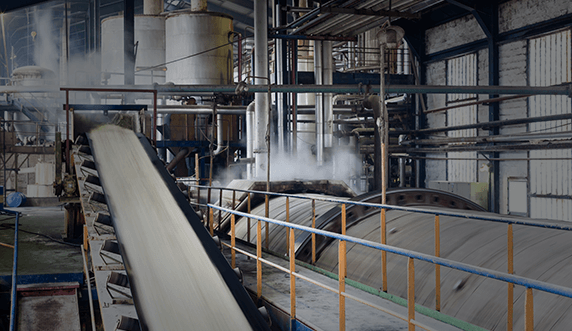

- Steel industry

- Rolling Mills and plants

- Port applications

- Oil industries

- Earth-moving industries

- Plastic Industries

- Plastic Industries

- Food industries

- Printing Industries

- Fertiliser industries

- Textile industries

- Elevators

- Conveyors

- Compressors

- Blowers

- Cutters

Where To Find The Best Helical Gearbox Manufacturers?

Are you searching for high quality, industrial-grade helical gearbox? Then look no further than Santram Engineers. Their decades of experience and

their inventive and innovative solutions to all your industrial necessities have set them apart and made them the leading supplier of industrial gearboxes.

Have a look at Santram Engineer PVT. LTD and its vast product catalogue, consisting of industrial power transmission products, industrial gearboxes, electric motors and much more.

To know more, contact us at +91 96247 39393 or drop us a mail at sales@santramengineers.com.