In the simplest of terms, a gear is a toothed wheel that engages with another similar mechanism to alter the speed or direction of the transmitted motion. Usually, gears are used to increase the speed of rotation in the mechanism, alter the amount of force or torque, move the rotational motion to a different axis or reverse the direction of rotation.

Helical and Planetary Gearboxes are the two most popular gearboxes that are used extensively across industries. If you are looking for information on the mechanics of gears, here is a crisp yet in-depth article on the fundamentals of helical and planetary gearboxes.

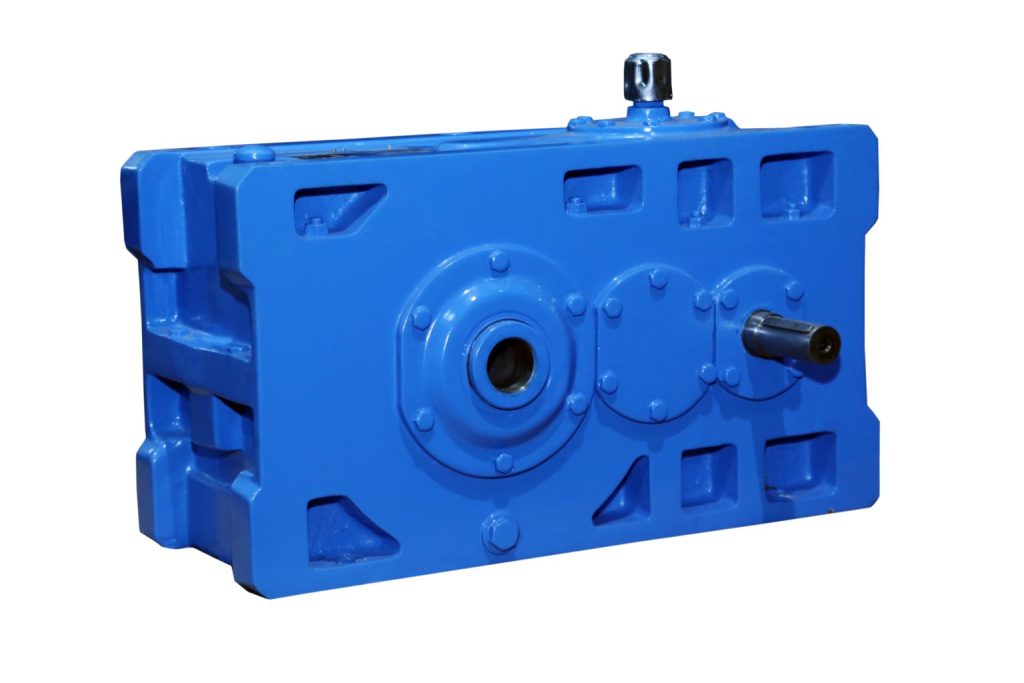

Helical Gearboxes

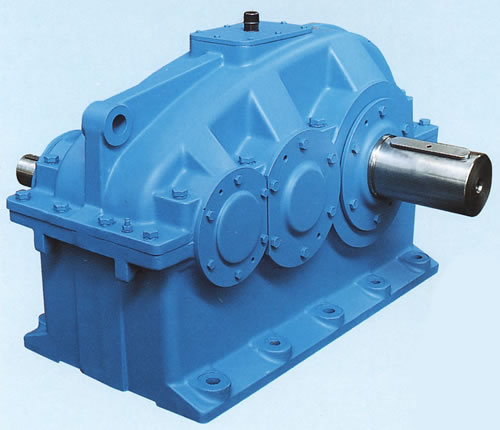

Helical gearboxes are high-performance gearboxes that are widely used in the fertilizer, printing, and earth-moving industries. They also find applications in the steel, rolling mills, power and port industries, etc. They are known to work at 98 percent efficiency, which is second only to planetary gearboxes.

Helical gearboxes are provided with teeth that are oriented at an angle to the shaft. Depending on their need for applications, helical gearboxes come in different configurations. There are single helical gears, double helical gears, and herringbone gears – each one varying in terms of the number and alignment of the gears.

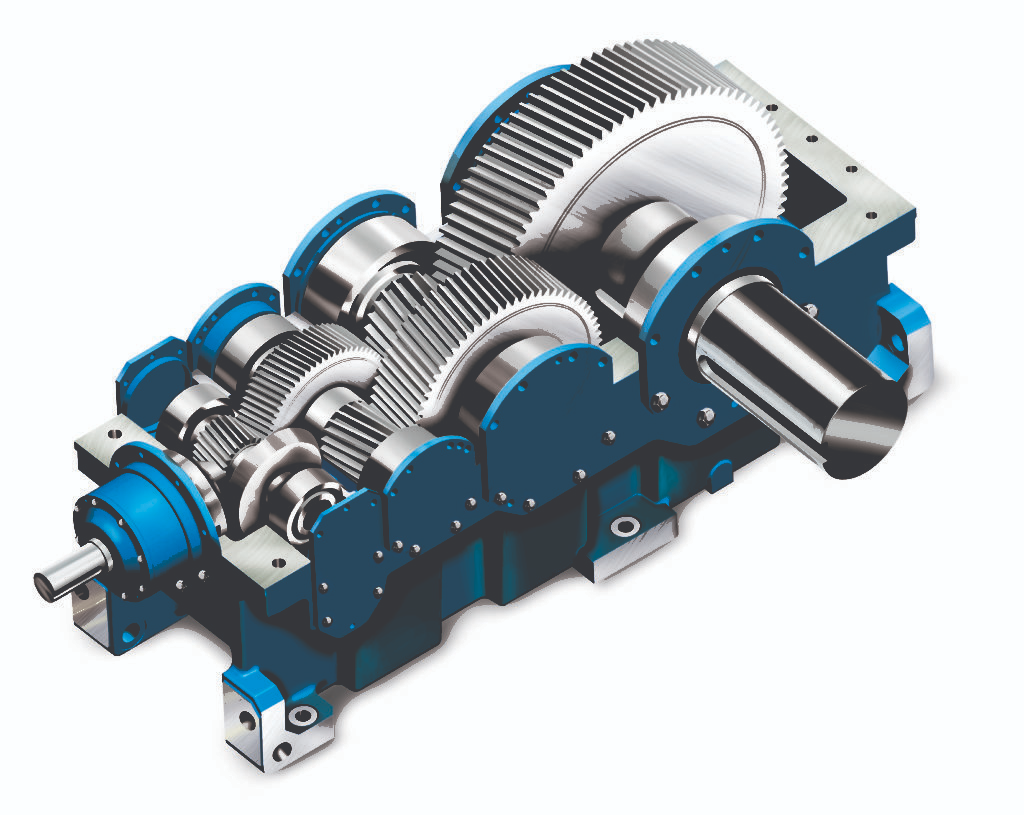

Working Principle of Helical Gearboxes

Helical gearboxes have a modular design and construction which offers several engineering and performance benefits. The gearbox offers a high degree of interchangeability and sub-assemblies.

The angular orientation of the teeth allows helical gearboxes to engage with more than one tooth to be in contact during the operation. This allows helical gearboxes to carry more load. As a result, helical gears are smoother in terms of operation and less noisy as compared to spur gears.

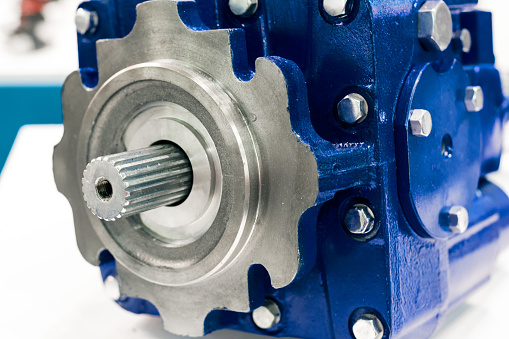

Planetary Gearboxes

These gears are also known as epicyclic gear systems and have a complicated design composed of three major components – a Central Sun Gear, multiple planetary gears in the middle, and an outer ring gear.

The Central gear in a planetary gearbox distributes the load to the inner planetary gears that are used to drive another gear or spindle. This is used to increase the torque as it powers multiple external gears to rotate in unison. With these gears, about 97 percent of energy is converted to energy production.

Working Principles of Planetary Gearboxes

The central or sun gear in the planetary gearboxes transmits torque to the planetary gears. These gears are typically mounted on a moveable carrier. Just like in the solar system, the planetary gears orbit around the sun gear and engage with the outer ring gear.

Due to their efficiency and high performance, planetary gears are the most popularly used gearboxes. They find application in several industries such as tractor manufacturing, construction equipment, turbine engines, and even electric screwdrivers.

Manufacturing High-Efficiency Gearboxes for Decades

Santram Engineering has been the leading supplier of transmission products for several decades. Their product portfolio includes industrial gearboxes, fluid couplings, electric motors, electromagnetic brakes, holdbacks, shrink discs and gear couplings, etc.

To know more about our high-efficiency gearboxes and other products, you can get in touch with us by writing to us at sales@santramengineers.com or calling us at 079-66168816