Have you ever wondered what makes your car move? It is the transmission system that helps to supply/transmit mechanical power from the car engine to the wheels. The transmission system basically includes a clutch, gearbox (also known as transmission), drive shaft or propeller shaft, universal joints, rear axle, wheel, and tires.

Each component attached to the engine plays a vital role in the entire power transmission process. The complete setup of the system of transferring power and energy from the engine to the wheels helps in maintaining the cruising speed of the car without any kind of hurdles or disturbance.

Now you may know how to change a tire or fix an engine, but do you know how to fix a broken transmission? After all, it is as important as all the other elements of your car. If you want your car to work at its optimum level then you must keep its Power Transmission Products solid and in good working condition.

Types of Transmission Systems

There are mainly two types of transmission systems available in the market

✔ Manual Transmission System

✔ Automatic Transmission System

Key Components Of a Manual Transmission System

Understanding the key components of a manual transmission system is essential for businesses and individuals involved in gearbox and power transmission products. Each part plays a vital role in ensuring smooth operation and efficiency.

Clutch

The clutch is the crucial link between the engine and the transmission. It engages and disengages the engine’s power to the transmission system, allowing the driver to shift gears seamlessly. When the clutch pedal is pressed, the clutch plates separate, interrupting the power flow and enabling gear changes without grinding.

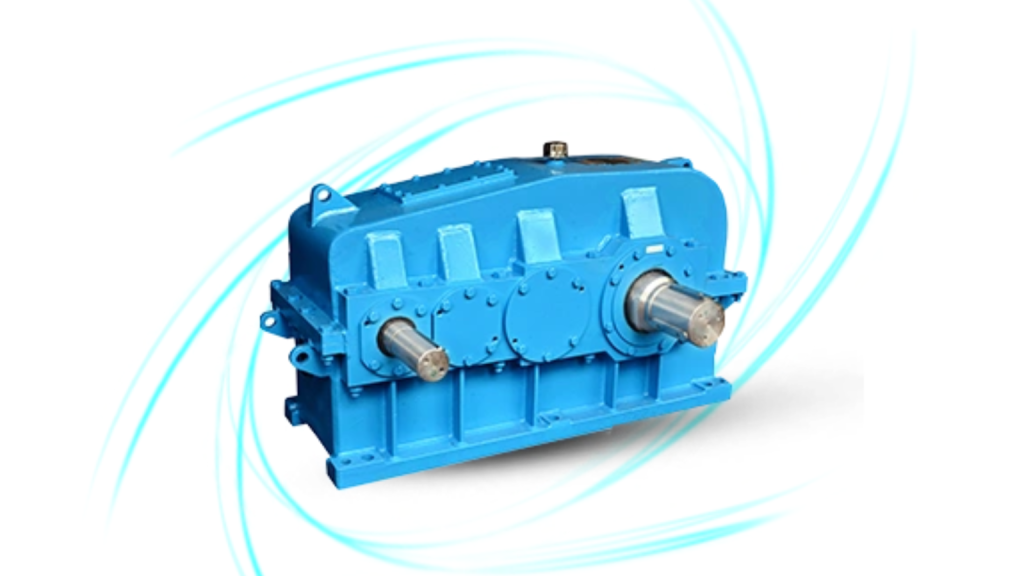

Gearbox

The gearbox, often referred to as the transmission, is where the power from the engine is converted to different torque levels. It contains various gears that adjust the engine’s output to suit different driving conditions. Manual gearboxes require the driver to select gears, providing greater control and efficiency, particularly in applications like industrial machinery and performance vehicles.

Propeller Shaft

The propeller shaft transmits power from the gearbox to the differential. It plays a vital role in connecting the transmission to the vehicle’s rear wheels, enabling motion. The shaft must withstand high torque levels while maintaining flexibility to accommodate changes in the vehicle’s angle during operation.

Differential

The differential is essential for distributing power to the wheels. It allows for differences in wheel speed, especially when turning, ensuring the vehicle maintains traction and control. A properly functioning differential enhances the vehicle’s performance and reduces tyre wear.

Live Axle

A live axle combines the axle housing and differential into a single unit. It connects the wheels and transmits power while allowing for movement. This component is critical in maintaining stability and providing consistent performance across various driving conditions.

Manual Transmission System:

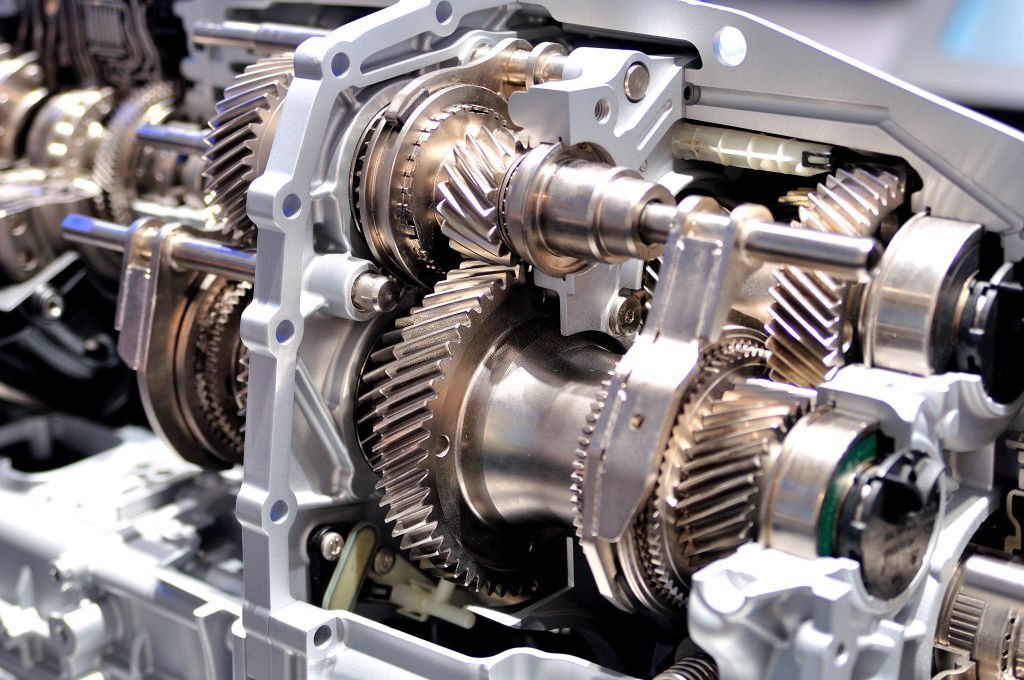

A manual transmission many times referred to as standard transmission requires a driver to select the gear within the automotive gearbox in order to achieve the desired speed. Speaking about how the entire system works, refer to the diagram below.

The green shaft which comes from the engine through the clutch allows you to get connected and disconnected with a push of a clutch pedal. I mean the moment you push the clutch pedal, the transmission gets disconnected so that the engine runs even when the car is standing still and once you release the pedal, the green shaft and gear turns at the same RPM as that of the engine.

Next is the red shaft, commonly known as the layshaft. The green shaft and the red shaft are directly connected with each other with the help of meshed gears. As the green shaft spins, the layshaft receives its power directly from the engine whenever the clutch is engaged.

Other than these two power transmission products, you will see a yellow shaft, blue ones which ride on the bearings and end up spinning the yellow ones (splined shaft).

Key Components of an Automatic Transmission System

Automatic transmission systems are sophisticated mechanical setups that enable seamless gear shifting without driver intervention. Understanding their key components can help businesses and individuals optimise the performance and maintenance of their power transmission products.

Planetary Gearbox

At the heart of the automatic transmission lies the planetary gearbox. This mechanical system comprises sun gear, planet gears, and a ring gear, allowing for various forward gear ratios and reverse. The design facilitates compactness and efficiency, making it a preferred choice for modern vehicles. Planetary gearboxes enable smooth transitions between gears, enhancing acceleration and overall drivability.

The Hydraulic System

The hydraulic system is crucial for the operation of an automatic transmission system. A specific transmission fluid is pumped under pressure by an oil pump through the valve body. This pressurised fluid controls the clutches and bands, allowing for precise gear engagement. The hydraulic system’s effectiveness is vital for maintaining smooth shifts and overall transmission performance.

Seals and Gaskets

To ensure the hydraulic system functions correctly, seals and gaskets play an essential role in preventing oil leaks. These components maintain pressure within the transmission, which is critical for optimal performance. Any leakage can lead to decreased efficiency and potential damage to the transmission system.

The Torque Converter

The torque converter acts as a fluid coupling between the engine and the transmission. It allows the vehicle to stop while still in gear, preventing stalling. By multiplying engine torque during acceleration, the torque converter enhances the vehicle’s responsiveness and performance.

Governors and Sensors

Governors and sensors monitor vehicle speed and motion, determining when to shift gears. These automatic transmission components provide real-time data to optimise performance and efficiency, ensuring gear changes occur at the most advantageous times.

Transmission Control Module (TCM)

In modern vehicles, the Transmission Control Module (TCM) is crucial for controlling the automatic transmission. This computer controls all shift points, directing electrical solenoids to ensure seamless gear changes. The TCM enhances overall vehicle performance and can adapt to changing driving conditions, contributing to a more efficient driving experience.

How Does an Automatic Transmission System Work?

An automatic transmission system simplifies driving by automatically changing gear ratios as the vehicle moves. At its core, the system uses a combination of hydraulic pressure, electronic controls, and mechanical components to shift gears without driver input.

When the engine runs, it drives the torque converter, which multiplies torque and transmits power to the transmission. The hydraulic system, powered by an oil pump, sends transmission fluid under pressure to engage the appropriate clutches and bands. This action allows the planetary gear sets to provide various gear ratios.

The TCM monitors vehicle speed and load, adjusting shift points for optimal performance. Sensors provide real-time feedback, ensuring smooth transitions and efficient power delivery. This seamless integration of components results in a smoother driving experience, better fuel efficiency, and reduced wear on the drivetrain, making automatic transmissions a popular choice for modern vehicles.

Frequently Asked Questions

1. What are the main types of transmission systems?

Transmission systems generally fall into two categories: manual and automatic. Manual transmissions need the driver to shift gears manually, while automatic counterparts automatically adjust gears based on speed and load. Each type has distinct advantages, such as driver control in manual systems and ease of use in automatics.

2. How do I know if my transmission system is failing?

Signs of a failing transmission system may include slipping gears, unusual noises, fluid leaks, or warning lights on the dashboard. If you experience delayed shifts or the vehicle hesitates while accelerating, it’s crucial to have your transmission components inspected promptly.

3. What role does transmission fluid play in a transmission system?

Transmission fluid is vital for lubrication, cooling, and hydraulic pressure within the system. It ensures the smooth operation of transmission components and helps to prevent overheating. Regularly checking and changing the transmission fluid is essential for maintaining optimal performance.

4. Can I upgrade my transmission components for better performance?

Yes, upgrading specific transmission system parts can enhance performance. Options include high-performance clutches, aftermarket gear sets, or improved torque converters. These upgrades can provide better responsiveness and efficiency, especially for vehicles used in demanding applications.

5. How is the Gearbox of a manual transmission system different from that of an automatic transmission system?

A gearbox of a manual transmission system is far better than that of the automatic one. It requires a more active role on the part of the driver. I mean the driver gets more control over the dynamics of the car in terms of both stopping and speeding the vehicle. While on the other hand, an automotive or planetary gearbox does switching of the gears on its own.

Being a driver you do not need to add much input to make the system work effectively. The only control you have in your hand is to put the car into the forwarding or reverse position.