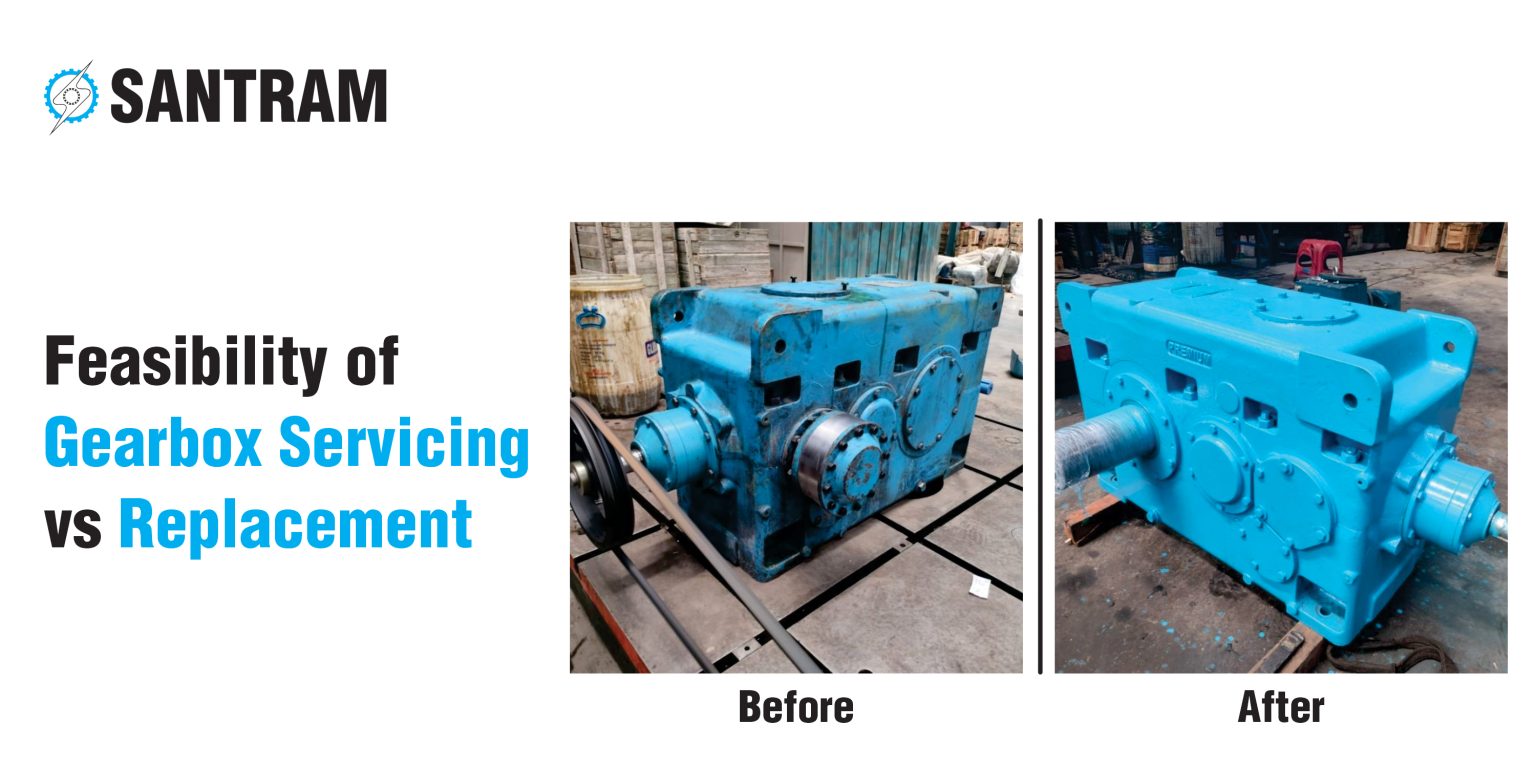

In the industrial sector, gearboxes play a critical role in the operation of machinery. As such, ensuring their reliability is paramount for businesses that depend on them. Companies face a pivotal decision when it comes to gearbox maintenance: should they service their existing gearboxes or replace them altogether? Understanding the feasibility of gearbox servicing versus replacement is essential. This discussion aims to provide insights into the industrial gearbox service landscape, highlighting its importance and the economic considerations involved.

What is Gearbox Servicing?

Industrial gearbox service refers to the systematic process of inspecting, maintaining, and repairing gearboxes used in various industrial applications. This service encompasses a range of activities, from routine checks to in-depth repairs, aimed at restoring and enhancing gearbox performance. It is designed to prolong the operational lifespan of gearboxes, ensuring they function efficiently and reliably over time.

Common Industrial Gearbox Service Procedures

1. Inspection

Regular inspections are the foundation of effective gearbox servicing. Technicians conduct thorough assessments to identify potential issues, such as wear and tear, misalignments, and oil contamination. Early detection of problems can prevent costly breakdowns, making inspection a critical aspect of gearbox maintenance.

2. Maintenance

Scheduled maintenance is essential for optimal gearbox performance. This includes tasks such as oil changes, lubrication, and alignment checks. Proper maintenance not only keeps gearboxes running smoothly but also reduces the likelihood of unexpected failures. Businesses should consider inquiring about industrial gearbox service prices when planning their maintenance schedules, as proactive care can save significant costs in the long run.

3. Repairs

When issues are identified during inspections, timely repairs are crucial. Common repairs may involve replacing worn components, sealing leaks, or addressing structural damage. Businesses often want to know, “How much does gearbox repair cost in India?” Repair costs can vary based on the complexity of the issue and the specific parts needed. However, addressing repairs promptly can prevent more extensive and expensive damage.

Benefits of Industrial Gearbox Servicing

1. Cost-effectiveness

One of the primary advantages of gearbox servicing is cost-effectiveness. Routine servicing can be significantly cheaper than a complete gearbox replacement. By prioritising consistent maintenance and prompt repairs, companies can prolong the lifespan of their gearboxes and steer clear of the considerable expenses related to purchasing new units. Understanding the industrial gearbox service cost helps businesses allocate budgets effectively for maintenance versus replacement decisions.

2. Extended Lifespan

Serviced gearboxes typically enjoy a longer operational life. Regular maintenance and repairs address minor issues before they escalate, resulting in improved reliability and reduced downtime. By keeping gearboxes in good condition, businesses can maximise their return on investment and improve productivity.

3. Improved Efficiency

Gearbox servicing leads to enhanced efficiency in machinery operations. Well-maintained gearboxes operate more smoothly, resulting in reduced energy consumption and lower operational costs. Companies that prioritise gearbox repair cost consideration can often achieve better overall performance, which positively impacts their bottom line.

What is Gearbox Replacement?

Gearbox replacement involves the complete removal of a faulty or outdated gearbox and the installation of a new or refurbished unit. This process is typically considered when servicing is no longer viable due to extensive damage or when the gearbox no longer meets the operational demands of the machinery. Understanding when and why to replace a gearbox is critical for businesses aiming to maintain efficiency and minimise downtime.

Situations Warranting Replacement

1. Severe Damage

One of the most common reasons for gearbox replacement is severe damage. If a gearbox has suffered a catastrophic failure, it may be more cost-effective to replace it rather than attempt repairs. Damage could include broken gears, severe casing cracks, or catastrophic bearing failures that compromise the gearbox’s integrity. In such cases, the industrial gearbox service may not be feasible, prompting businesses to opt for replacement instead.

2. Outdated Technology

As technology advances, older gearboxes may not keep pace with newer standards in efficiency and performance. If a gearbox is outdated, it may lack the capabilities required for modern machinery or fail to meet energy efficiency regulations. In this situation, replacement not only addresses the immediate issues but also provides an opportunity for businesses to upgrade to a more efficient system.

Benefits of Gearbox Replacement

1. Enhanced Performance

One of the key benefits of gearbox replacement is enhanced performance. Newer gearboxes are designed with improved engineering, offering better torque delivery and more reliable operation. This results in higher efficiency and productivity levels, which can be crucial for businesses aiming to stay competitive in their respective markets. A new gearbox can help reduce operational costs by minimising energy waste and optimising machinery output.

2. New Technology Integration

Replacing a gearbox provides an opportunity to integrate the latest technology. Modern gearboxes often feature advanced materials, better sealing systems, and more efficient lubrication methods. These advancements can lead to significant improvements in overall machinery performance and reduce the need for frequent servicing. Businesses that invest in new gearboxes can benefit from enhanced automation features and smart technology integration, which can lead to more streamlined operations.

3. Warranty and Support

Another significant advantage of gearbox replacement is the warranty and support that comes with new units. Most manufacturers offer warranties that provide coverage for parts and labour, offering businesses peace of mind in their investment. Additionally, new gearboxes typically come with improved customer support and service options, which can enhance operational reliability. Understanding the industrial gearbox service cost associated with these benefits can help businesses make informed decisions.

Cost Analysis

1. Initial Costs of Servicing vs. Replacement

When businesses evaluate their gearbox maintenance options, one of the first considerations is cost. Industrial gearbox service price varies significantly depending on the extent of service required. Basic inspections and routine maintenance can be relatively inexpensive, often falling within a few thousand rupees. In contrast, gearbox replacement typically involves higher upfront costs. New gearboxes can range from tens of thousands to several lakhs, depending on specifications and requirements.

Businesses should also consider that while servicing may seem cheaper initially, costs can accumulate if repeated maintenance is necessary. Conversely, investing in a new gearbox may represent a larger initial expense but can yield long-term savings through enhanced efficiency and reduced breakdowns.

2. Long-Term Financial Implications

The long-term financial implications of servicing versus replacement are crucial. Servicing can extend the lifespan of a gearbox, potentially delaying the need for replacement. However, frequent repairs may also indicate that a gearbox is nearing the end of its useful life, leading to a cycle of ongoing costs.

On the other hand, while replacing a gearbox may require a significant initial investment, it can also result in substantial savings over time. Newer models generally offer improved energy efficiency and performance, which can lead to lower operational costs. Thus, companies must consider not only the immediate costs but also the expected lifespan and efficiency of the gearbox.

3. Hidden Costs in Both Options

Both industrial gearbox servicing and replacement can involve hidden costs that businesses must be aware of. For servicing, these can include the costs associated with downtime during repairs and any unexpected issues that arise during maintenance. If a gearbox requires more extensive work than initially estimated, expenses can escalate quickly.

For replacement, hidden costs might involve the installation process, potential training for staff on new systems, and the costs of disposing of the old gearbox. Understanding these hidden costs can help businesses make more informed decisions.

Time Considerations

1. Time Required for Servicing

The time required for industrial gearbox servicing can vary widely based on the type and extent of service needed. Routine maintenance tasks like lubrication or oil changes might take just a few hours, while more extensive repairs could require several days. However, quick turnaround times can often minimise production downtime.

2. Time Required for Replacement

Replacing a gearbox is generally a more time-consuming process. It involves the removal of the old unit, the installation of the new gearbox, and thorough testing to ensure proper operation. Depending on the complexity of the installation and the type of machinery involved, the replacement process can take anywhere from a few days to over a week.

3. Impact on Production Downtime

Production downtime is a critical consideration for businesses. While servicing may allow for quicker repairs, the cumulative effect of frequent maintenance can lead to significant operational disruptions. In contrast, a single, well-planned replacement can streamline operations in the long run, albeit at the cost of initial downtime. Companies should factor in how downtime will affect overall productivity and revenue when weighing their options.

Factors Affecting Service Quality

The quality of gearbox service can vary based on several factors, including the expertise of the technicians, the quality of replacement parts used, and adherence to established procedures. Choosing a reputable industrial gearbox service provider ensures that the service meets industry standards and delivers reliable performance.

Industry Standards and Certifications

Adherence to industry standards and certifications is crucial for ensuring quality and reliability in both servicing and replacement. Certifications like ISO 9001 demonstrate a commitment to quality management practices, which can reassure businesses about their investment in gearbox services or replacements.

Decision-Making Criteria

Choosing between gearbox servicing and replacement requires careful consideration of several critical factors:

1. Age and Condition of the Gearbox

The age and condition of the gearbox play a significant role in the decision-making process. Older gearboxes with extensive wear and tear may be less reliable, prompting the need for replacement. Conversely, if the gearbox is relatively new and well-maintained, servicing may be a more viable option. Regular assessments can help determine its overall health, influencing the decision.

2. Operational Requirements

Understanding operational requirements is essential. If machinery demands higher performance or efficiency, an outdated gearbox may no longer suffice. In such cases, replacing it with a more advanced model could enhance productivity. Conversely, if current operations are stable and performance is satisfactory, continuing with industrial gearbox service may be appropriate.

3. Budget Constraints

Budget constraints can significantly impact the decision. While servicing is often more economical upfront, replacement might be justified if long-term savings are considered. Businesses must evaluate the service cost against potential downtime and repair costs to find the best financial solution.

Frequently Asked Questions

1. When should I consider servicing my gearbox instead of replacing it?

If your gearbox shows minor wear and tear but operates reliably, servicing may be the best option. Regular maintenance can address small issues before they escalate, making it a cost-effective choice for extending the gearbox’s lifespan. If you notice strange noises or decreased performance, a professional inspection can help determine whether servicing is adequate.

2. How can I determine if my gearbox needs replacement?

Signs that your gearbox may need replacement include frequent breakdowns, persistent leaks, or significant damage that repair costs exceed half the replacement cost. If you find your gearbox struggling to meet operational demands, consider a replacement to ensure efficient and reliable performance.

3. What should I look for in an industrial gearbox service provider?

When selecting a service provider, ensure they have a strong reputation and industry certifications. Look for experience in gearbox repairs and refurbishment, as well as access to high-quality parts. Customer reviews and testimonials can provide insights into their service quality and reliability.

4. Are there specific regulations I need to follow when replacing gearboxes?

Yes, businesses must adhere to industry-specific regulations and safety standards when replacing gearboxes. This includes compliance with local safety codes and environmental regulations, especially when disposing of old units. Always consult relevant guidelines to ensure compliance during replacement projects.

Santram Engineers Provides Custom Industrial Gearbox Service and Replacement

Regular industrial gearbox service is essential for maintaining the efficiency and longevity of your machinery. Whether you need routine maintenance or replacement, our experienced team is here to help.

Take the proactive approach—invest in servicing today to avoid costly breakdowns tomorrow. With competitive pricing and tailored solutions to fit your unique needs, we ensure your operations run smoothly.

Contact us at +91 96247 39393 or drop us an email at sales@santramengineers.com for a detailed assessment and a personalised quote. Let us be your trusted partner in maximising performance and minimising downtime.